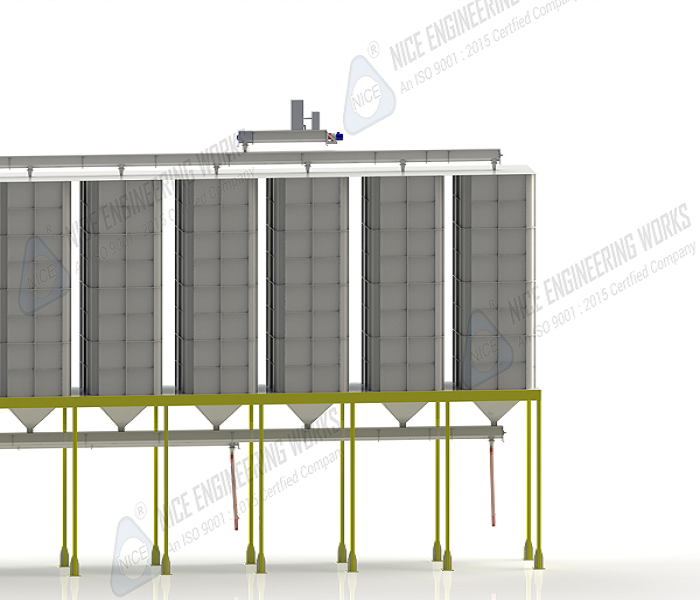

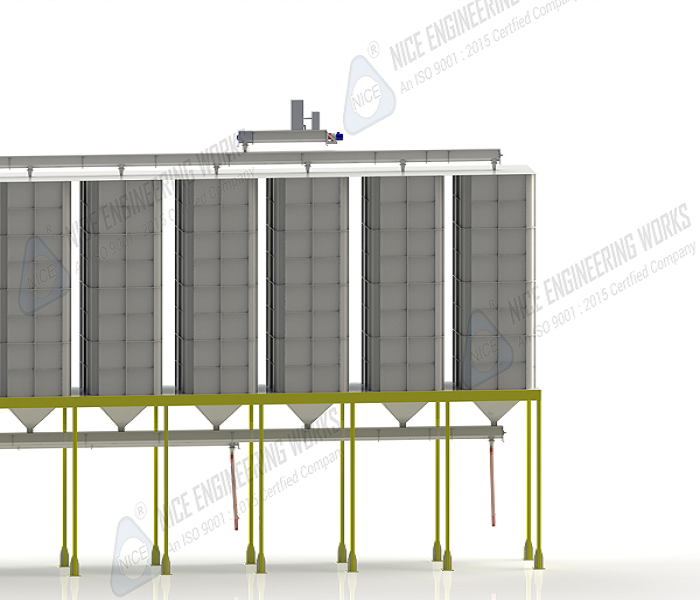

A silo is a structure for storing grain and bulk materials, where material pours in continuously. We have made various storage bins with customizable sizes. Bins are manufactured in the factory as well as on sight using S.S., M.S. material that has a handling capacity of 10-150 ton. However, bins are carefully engineered and designed. Fumigation is applied to the Bins to protect the raw material from pests and insects and to achieve hygiene. The Hull of the bins do not allow the grains to trap inside, hence our bins are super hygienic. We make special & tested bins to suit customer requirements.

Specification:

- Fumigated surface.

- Moisture proof.

- Fireproof.

- High-quality bins.

- Modular construction.

- customizable size.

Utilization

Nice Engineering Works is offering Polisher machine for toor dal. Toor Dal Polisher machine is simple in design and simple to operate and maintain. A horizontal lather roller is located inside the body of the polisher machine. Our polisher machine is used in the post-treatment plan for polishing toor dal. This Polisher Machine is specialized for toor dal.

Operation

The oily material enters the polisher machine through the inlet hopper, which is located on the top side of the machine. Inside the polisher machine, a roller with a leather polish strap rotates to polish and shine the material. The finished materials exit from the machine through the outlet hopper, which is located on the machine’s bottom side.

Features

- Faster return on investment.

- Compact Design

- Minimum power consumption and low product wastage.

- It is easy to operate.

- High Power Motor

Utilization

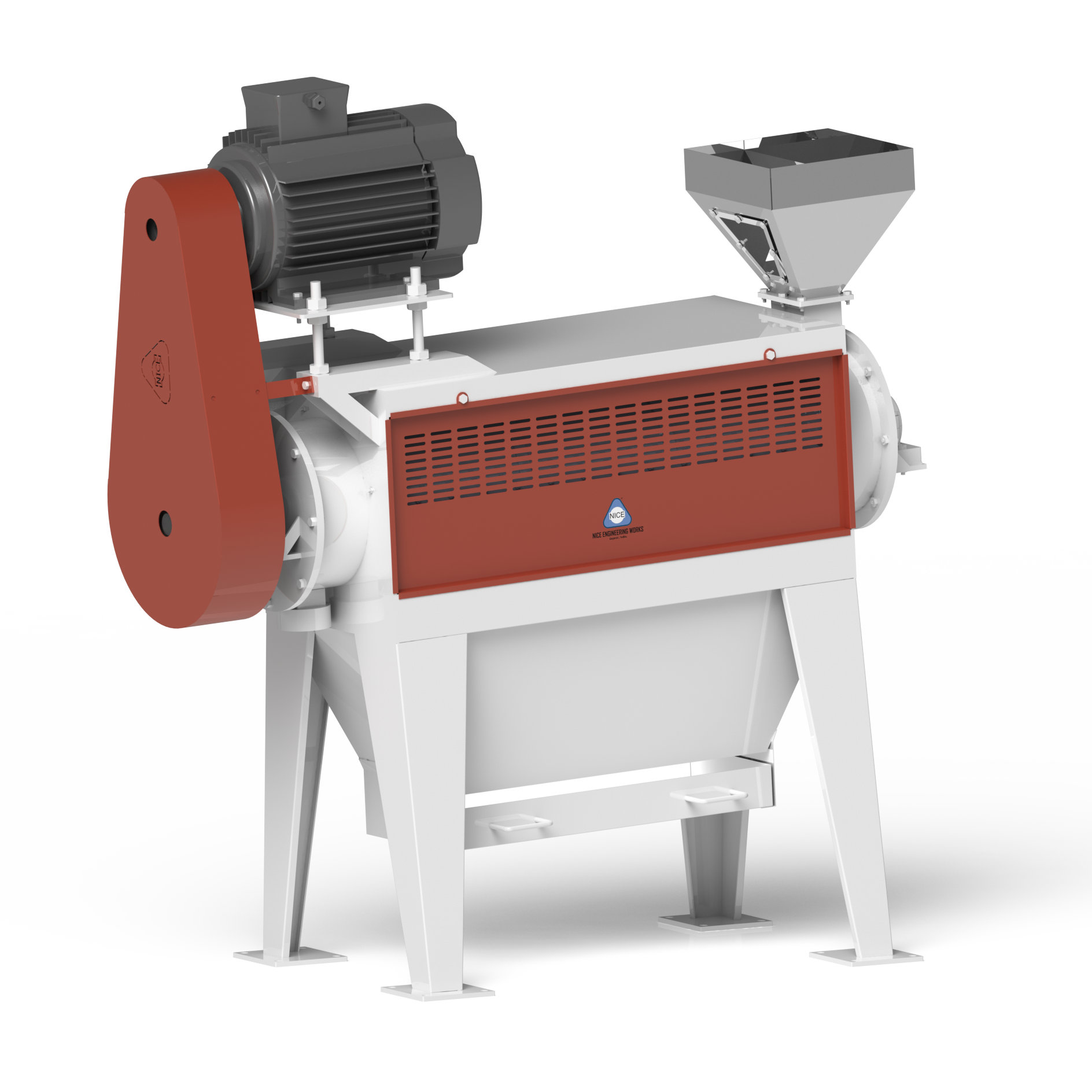

Our professional designers and skilled Engineers have designed this machine in such a way that it lives up to all the expectations and forecasts of the customers. Our Rubber Roll Machine is used in a wide range of applications such as Pre-treatment, Obtaining gota, De-husking grains, Rice, pulses, corn, and Separation of impurities.

Operation

This machine is simple in construction and easy to operate & maintain. The inlet box consists of a dead box with a magnetic inlet. Magnet in inlet box does not let any metal particle get inside. The Roller shaft is reinforced by a pedestal bearing. The horizontal Roller shaft rotates around the axis of the pedestal bearing. You can simply adjust processing speed with the help of an output slate valve. Finally, the stock drops onto the sieve following final processing. Eventually, the pure material is taken away from the outlet hopper.

Features

- Magnetic inlet.

- Adjustable sieve backed on the flange.

- Easy to operate.

- Adjust RPM with the help of frequency drive.

- Integrated design.

- Heavy-duty double roller bearing.

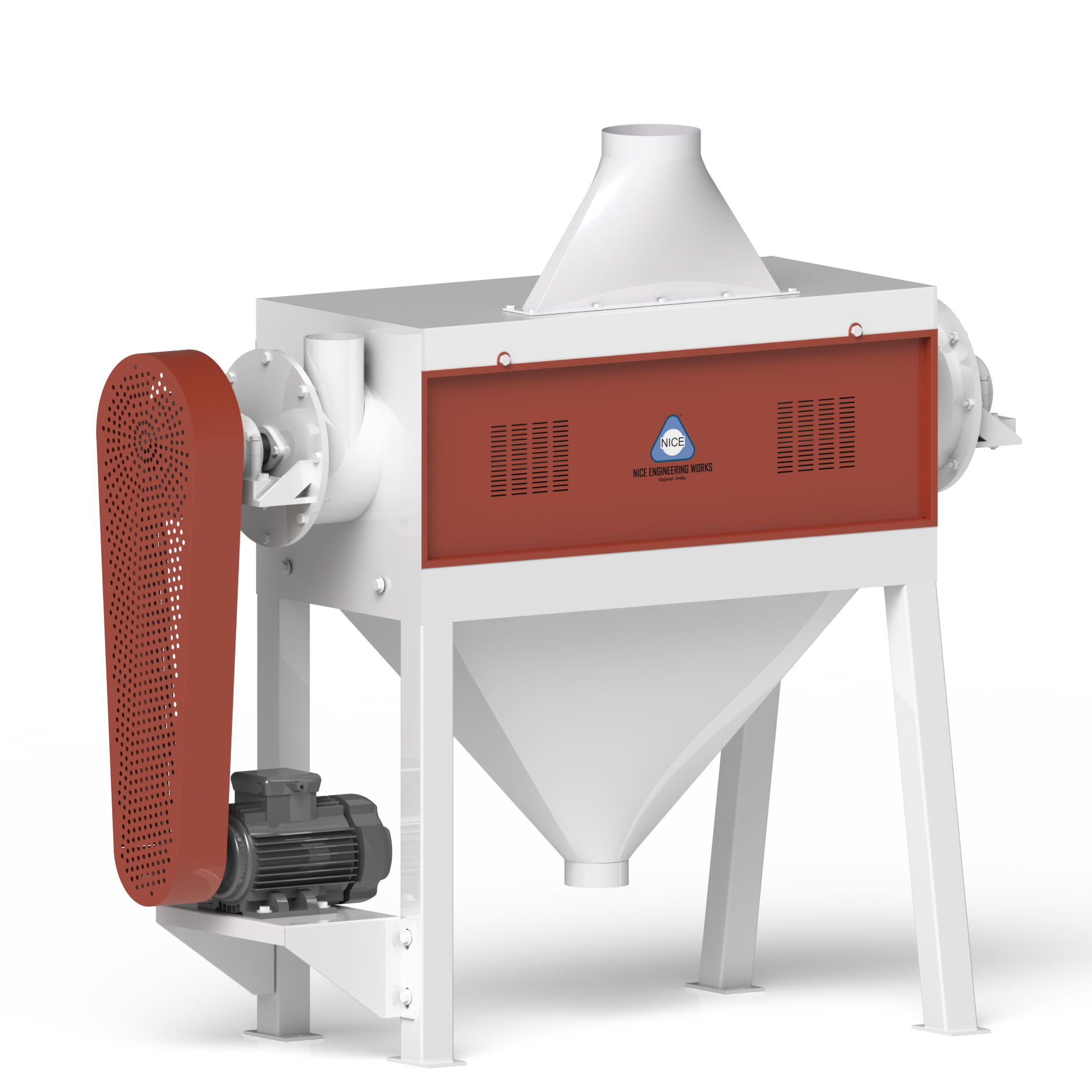

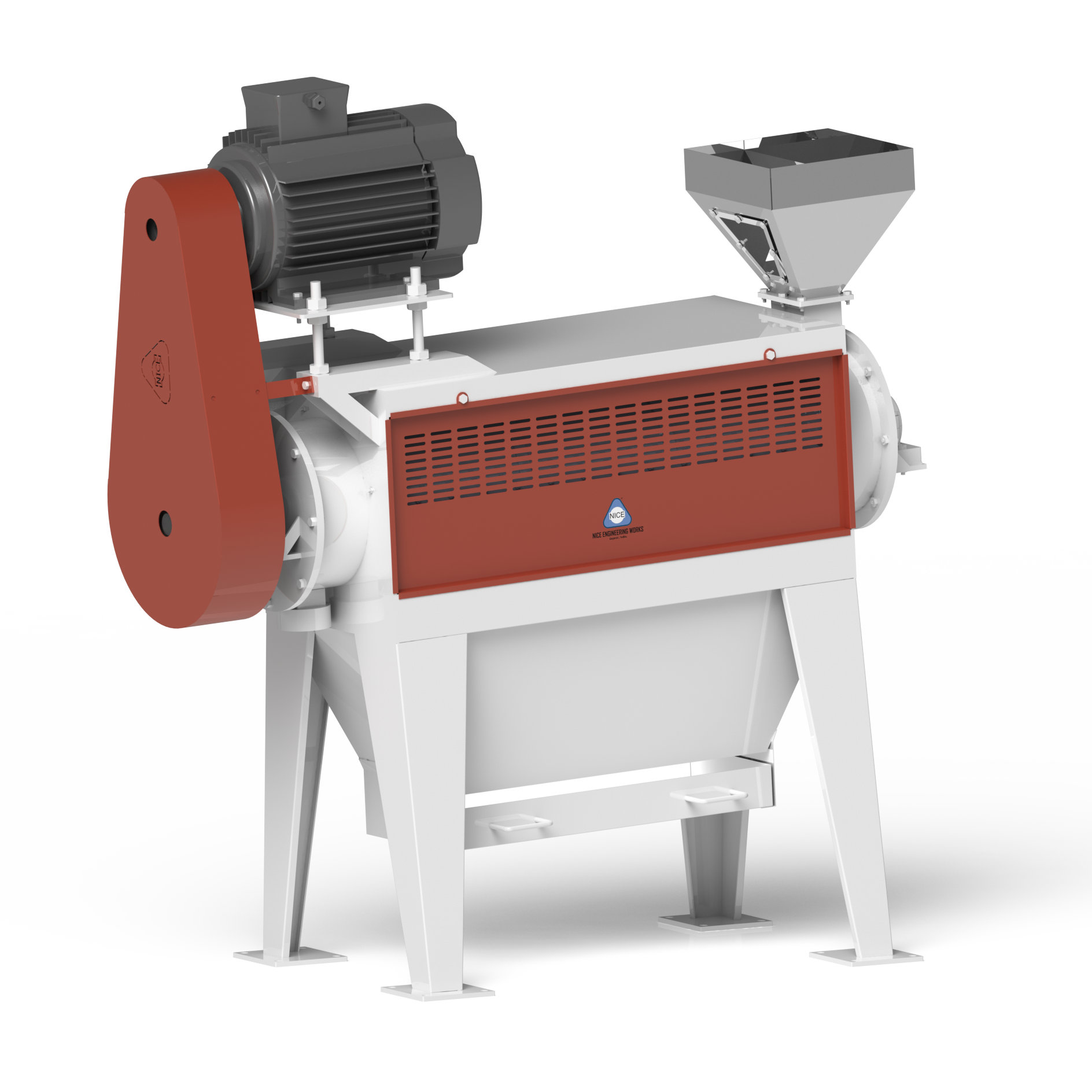

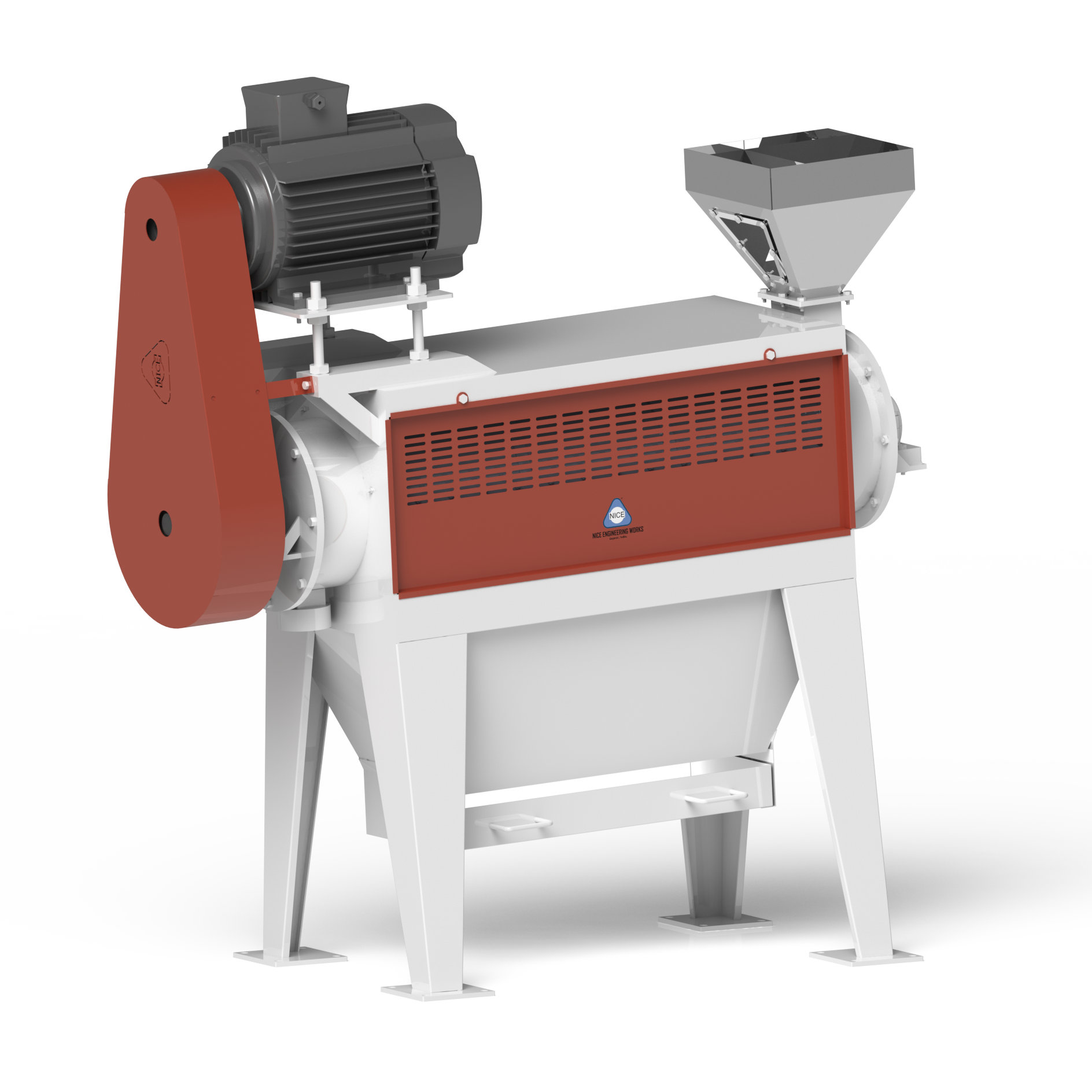

Utilization

Brush Roll machine is used to provide smooth and finalized touch to almost all types of grains and pulses such as lentils, chickpea, peas, beans, wheat, rice, rye, etc.

Operation

Brush Roll/Brush Polisher Machine is equipped with a Polishing Brush wooden strap attached to the rollers. It produces a small amount of friction to polish the material to removes bran from the surface of the material, resulting in better appearance and quality with the capacity of 6 to 8 tons per hour.

Features

- Heavy-duty parts with long service life.

- Simple to use.

- High yield.

- Provide perfect brightness.

- least breakage.

- long life of spare parts.

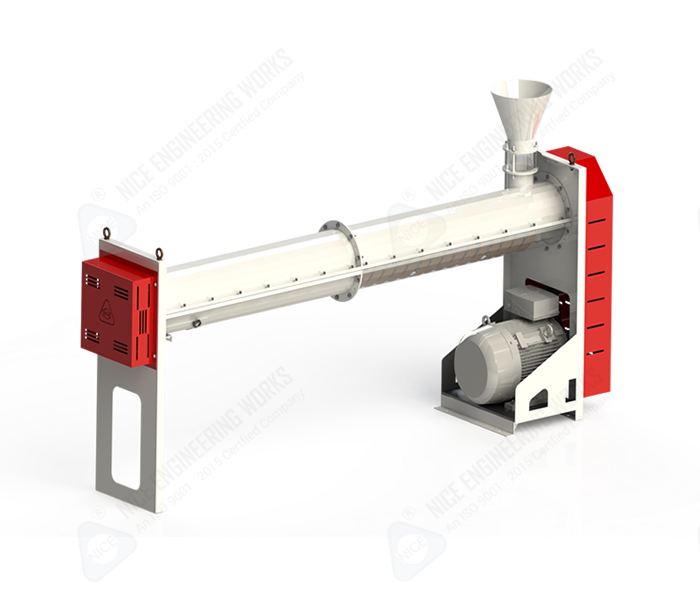

Utilization

We are a substantial food processing equipment manufacturer. We have been making untiring efforts and commitment to innovation. Our fatka machine is used in the post-treatment plan.

Operation

Fatka machine is used to break down different types of pulses like red lentils (Masoor), Cajanus cajan (Arhar Dal), black lentils(Urad Dal), chickpea(Chana Dal), etc. into perfect and definite shapes. Our machines are manufactured using the best quality components. It may be specified as it has four high-density fiber strips that lead to a minimum dissipate rate. We use heavy-strength material to maintain the sturdiness of our machines. Our machines are highly efficient and have fast throughput of 2 to 3 tons/hour.

Features

- High durability and easy maintenance.

- Fast processing.

- High quality bearings for smooth operation

Utilization

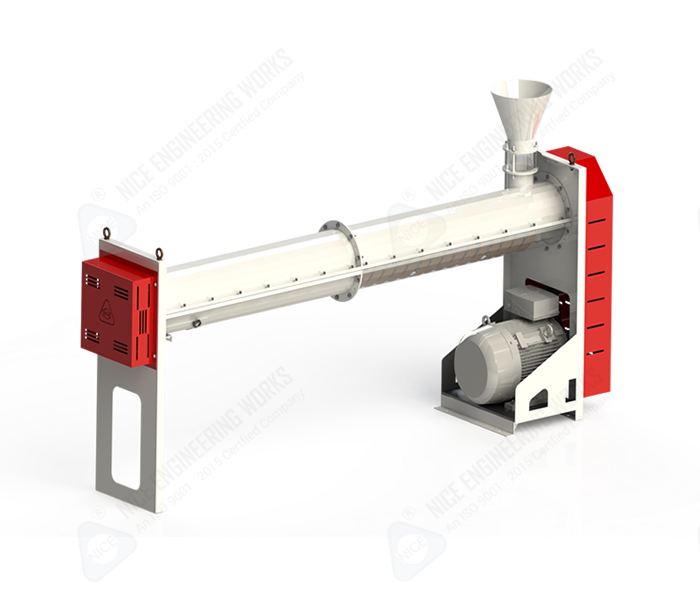

We are a substantial food processing equipment manufacturer. We provide the most reliable and productive devices that perform round the clock. We have been making untiring efforts and commitment to innovation. Our polisher machine is used in post-treatment plan and polishing pulse and Rice.

Operation

It provides a thorough and impacting effect on Rice and pulses. An inlet hopper is mounted at the top of the machine which enables the stock to get inside. The roller with leather polish strap rotates inside the sieve, gently rub the material, and provide it a shiny and smooth finishing. A round hole sieve is given at the bottom of the roller, whereby, smaller particles dropdown. An inclination of 9° of the machine body help reaching the product towards it’s destination.

Features

- Provides shiny and silky finish.

- High power motor.

- Leather for polishing.

- Perforated sheet.

- Adjustable sieve.

- Bearing with flange for smooth operation

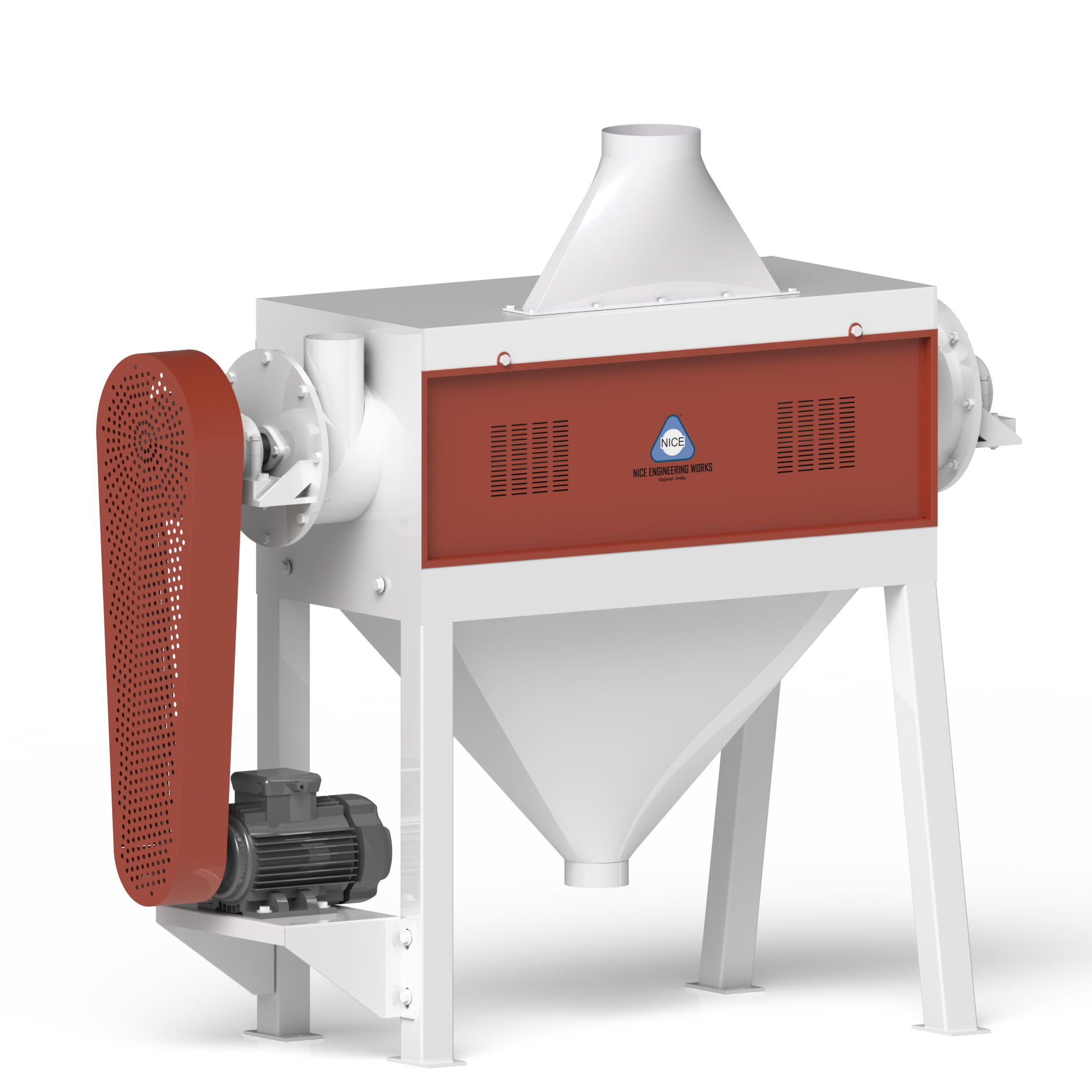

Utilization

Mini Scourer machine gives a final touch to the product. It is specially used for removing bran from the psyllium seed. It is used in applications such as Grading, Scouring, and Separation of mild impurities. It efficiently removes hull particle or surface contamination from the grain.

Operation

The stock is fed via the inlet, mounted on the top of the machine. The rotary part captures this material. The material is gently scoured. Scouring takes place due to friction. Finally, the pure material goes onto the outlet duct, and Impurities are guided to the exit via outlet ducts.

Features

- Fast throughput.

- High quality material leads to sturdiness.

- Extreme motor power.

- High quality bearings for smooth operation.

Utilization

The scourer machine gives a final touch to the product. Scouring machine is used in applications such as Scouring, and Separation of mild impurities.

Operation

The stock is fed via the inlet mounted on top of the machine. The rotary part captures this material. The food is gently scoured. Scouring takes place during friction. Finally, the isolated material goes onto the outlet duct, and Impurities are guided to the exit via outlet ducts.

Features

- Fast throughput.

- High quality material leads to sturdiness.

- Extreme motor power.

- High quality bearings for smooth operation.

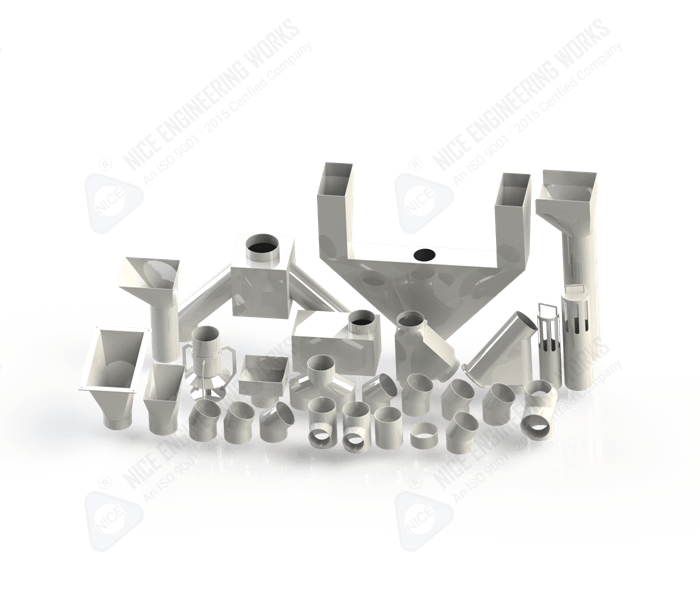

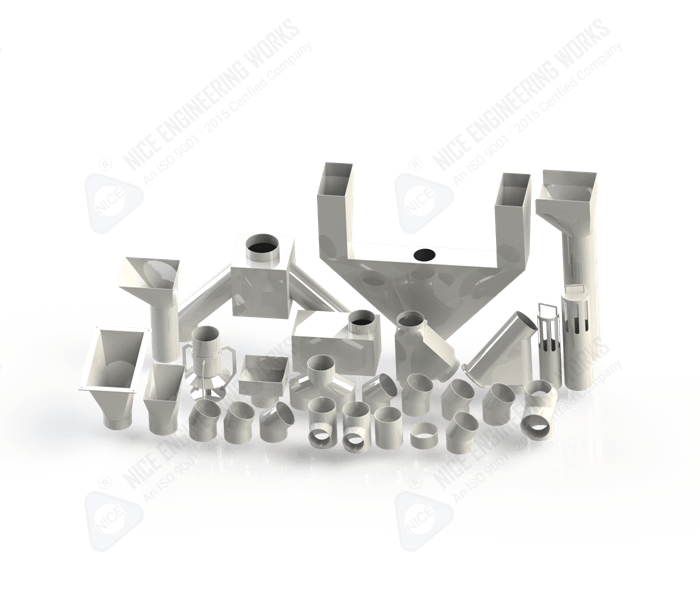

Our speed spout include a various types of products such as pipe, magnet box, segment, flat clamp, y-piece, packing branch, divider, dead box etc. we have designed our products to meet the requirement of the plant. Speed spout components are made up of Mild Steel, Stainless steel and other specially metals are also available upon request. Our speed spout can handle anything from a simple connection to diverting or splitting, managing flow, or product inspection.

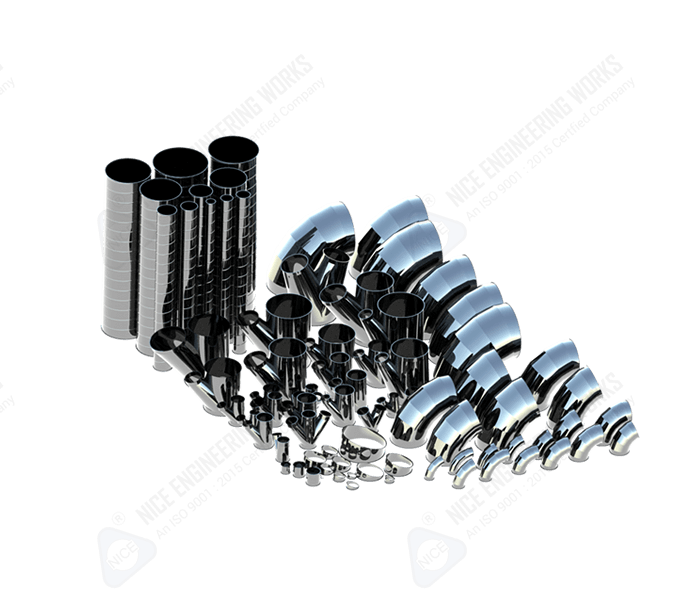

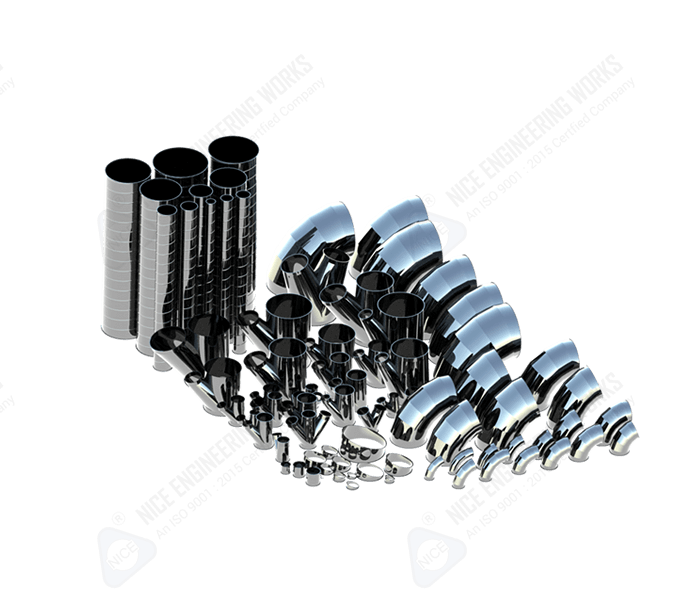

Dust Duct is the total system of pre-engineered, welded metal ducting and fittings are used for dust control work. There are different types of fittings in a full range in all diameters by half-inch increments. These types and sizes cover almost 100% of the requirements for air pollution and dust control systems, excepting very unusual or extremely large jobs. Dust Duct fittings such as transitions and tapers are made with short straight-end collars to permit joining by standard compressor couplings or flanges. Collar lengths are depending on diameter. Flared straight pipe and ells are normally supplied with one flange welded to one end, and the other flange loose so it can be welded in the field so both holes can be aligned to fit as required. Other fittings may have all flanges welded on. Note that longitudinal seams are normally centered top or bottom. Flanges are welded to the part so one bolt hope is in line with the seam. Fittings are mace with collars, even when flanged.

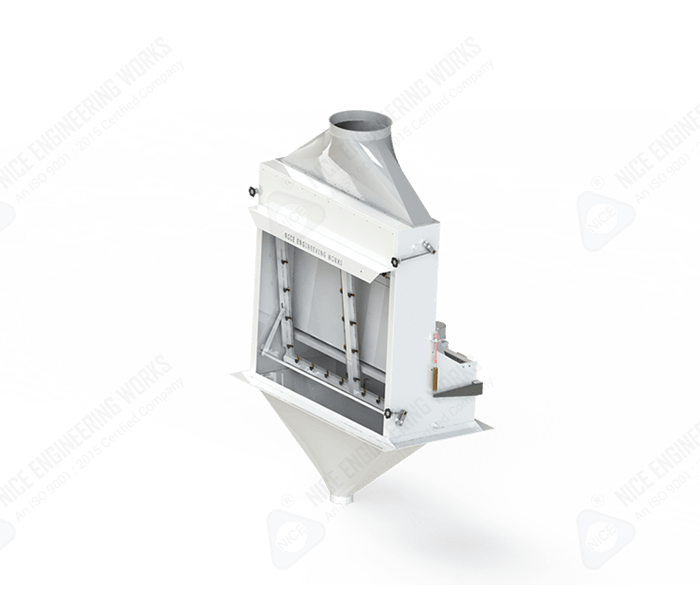

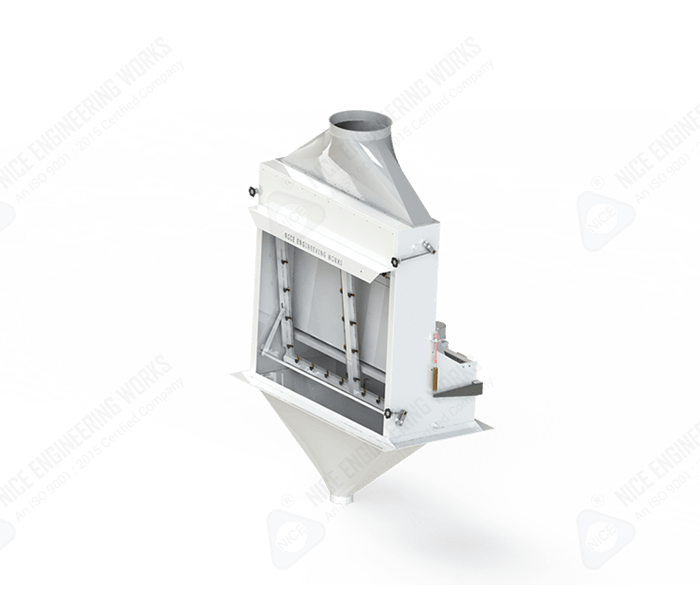

Vibration Aspiration Channel is used to collect dust particles, from the material, where it is in powder form. It is especially used in flour mill to remove the fine impurities.

Aspiration channel collects lighter particles from the material with the suction air created by pneumatic fans. Since, the material is in powder form, it requires a vibration to get the material removed. Hence, vibratory aspiration channel is equipped with vibratory motor. Light particles are sucked from the stock and sucked in the upright body into the outlet. Air can be managed through moving plates in the upright body. The sucked light particles can be inspected by transparent acrylic glass placed on the front of the machine. Movable plates are controlled by adjusting knob located outside the body.

Features

- High capacity and effortless maintenance.

- Reliable performance.

- Easy operation.

- High strength inspection glass.

- Low space and low power required.

- knobs for adjusting material throughput speed.

Air box is used with Pneumatic fans create suction air that draws lighter particles from the material into the Air Box. Lighter particles are sucked from the stock and sucked into the outlet through the upright body.

Features

- High capacity and effortless maintenance.

- Reliable performance.

- Easy to install.

- Low space and zero power required.

+91 99786 77165/ +91 7069012352

+91 99786 77165/ +91 7069012352