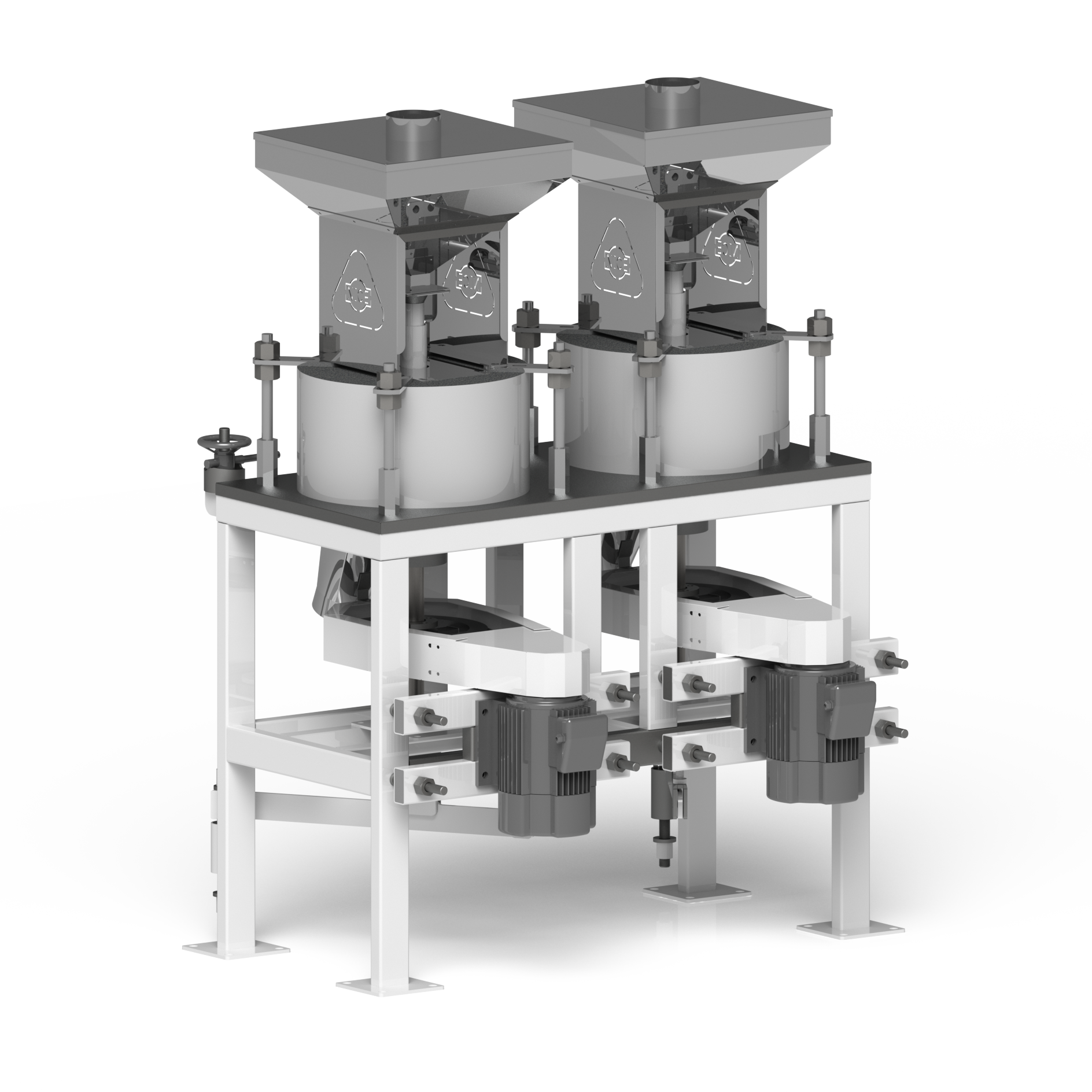

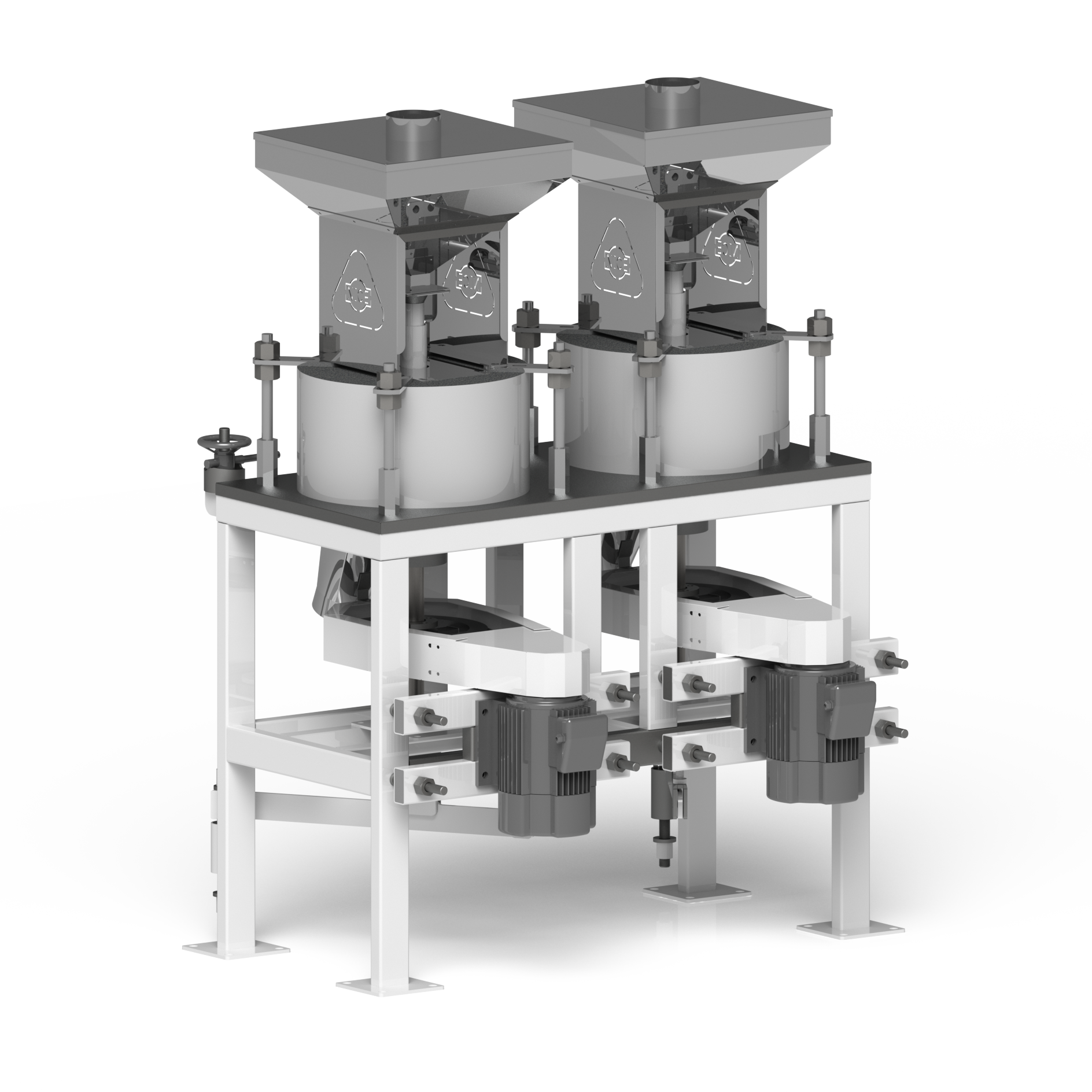

Utilization

Our Twin Psyllium Chakki has a sturdy structure which is used in various implementations like Psyllium Husk, Gola.

Operation

Raw material gets into the machine by the way of an inlet hopper. Two rolling stones crush the whole grain into Psyllium Husk. A hand operating knob is placed under the inlet hopper. Fine Psyllium Husk is subsequently thrown out with the help of the outlet segment.

Features

- Knob & Adjustable speed of material.

- High capacity.

- Pulley for high grip.

- Vertical shaft & dual bush for smooth operation.

- Fully automated.

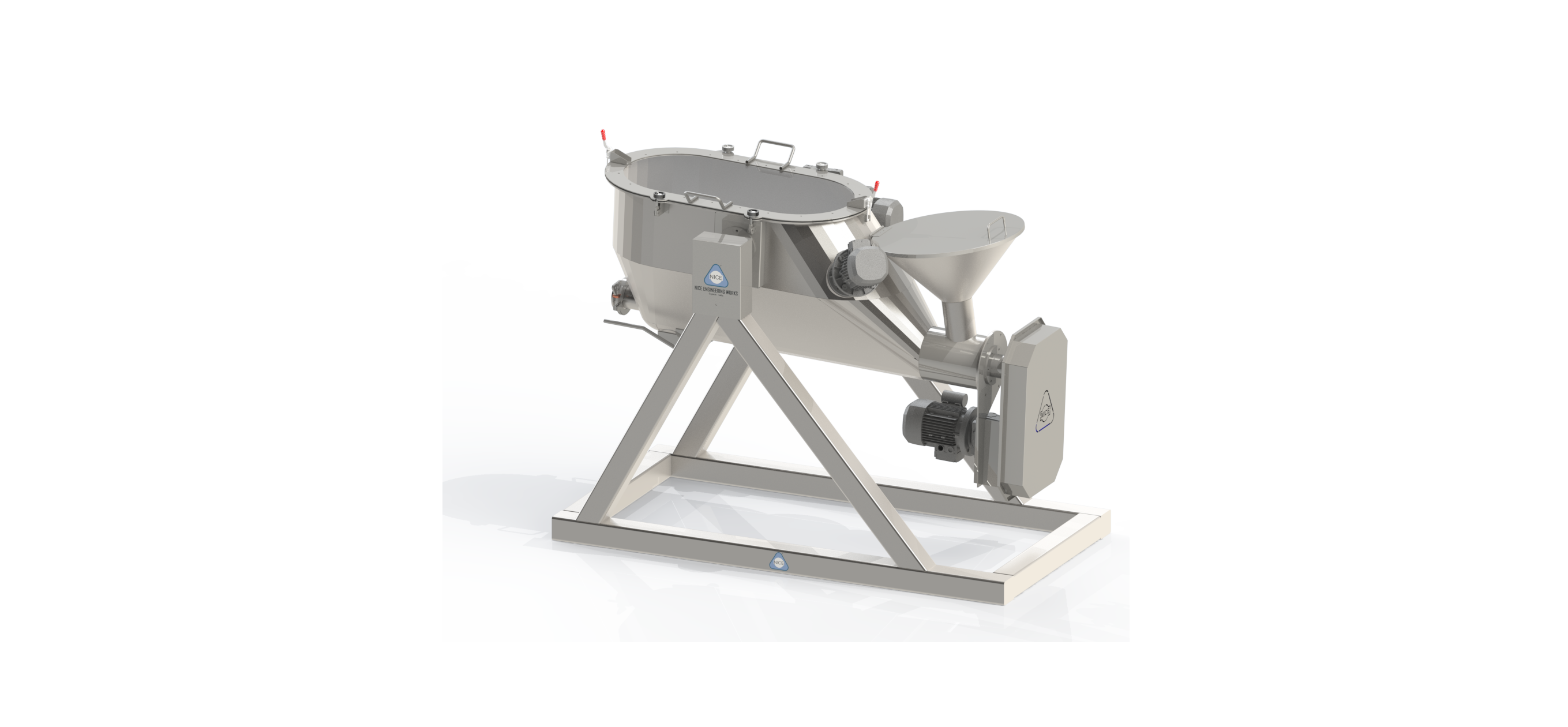

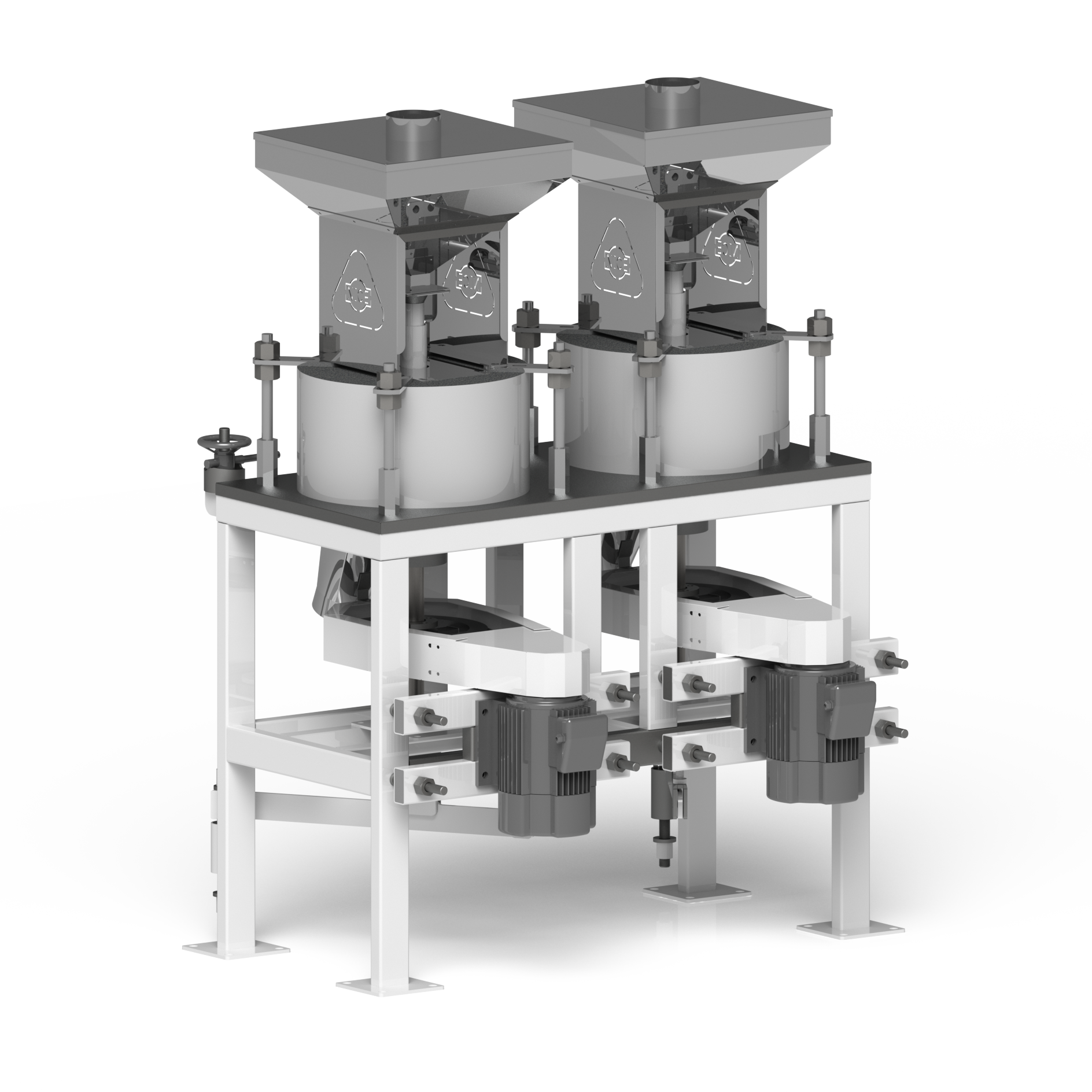

Utilization

Nice Engineering Works Introducing the Pulse Splitter Machine, has sturdy structure which is used in various implementations like flour mill, pulse splitting etc.

Operation

Raw material gets into the machine by the way of an inlet hopper. Two rolling stones crush the whole grain into fine flour. A hand operating knob is placed under the inlet hopper. Fine ground flour is subsequently thrown out with the help of the outlet segment.

Features

- Knob for Adjusting speed of material.

- High capacity.

- 5B pulleys for high grip.

- Vertical shaft and double bearing for smooth operation.

- Integrated design with S.S. body.

- Fully automated.

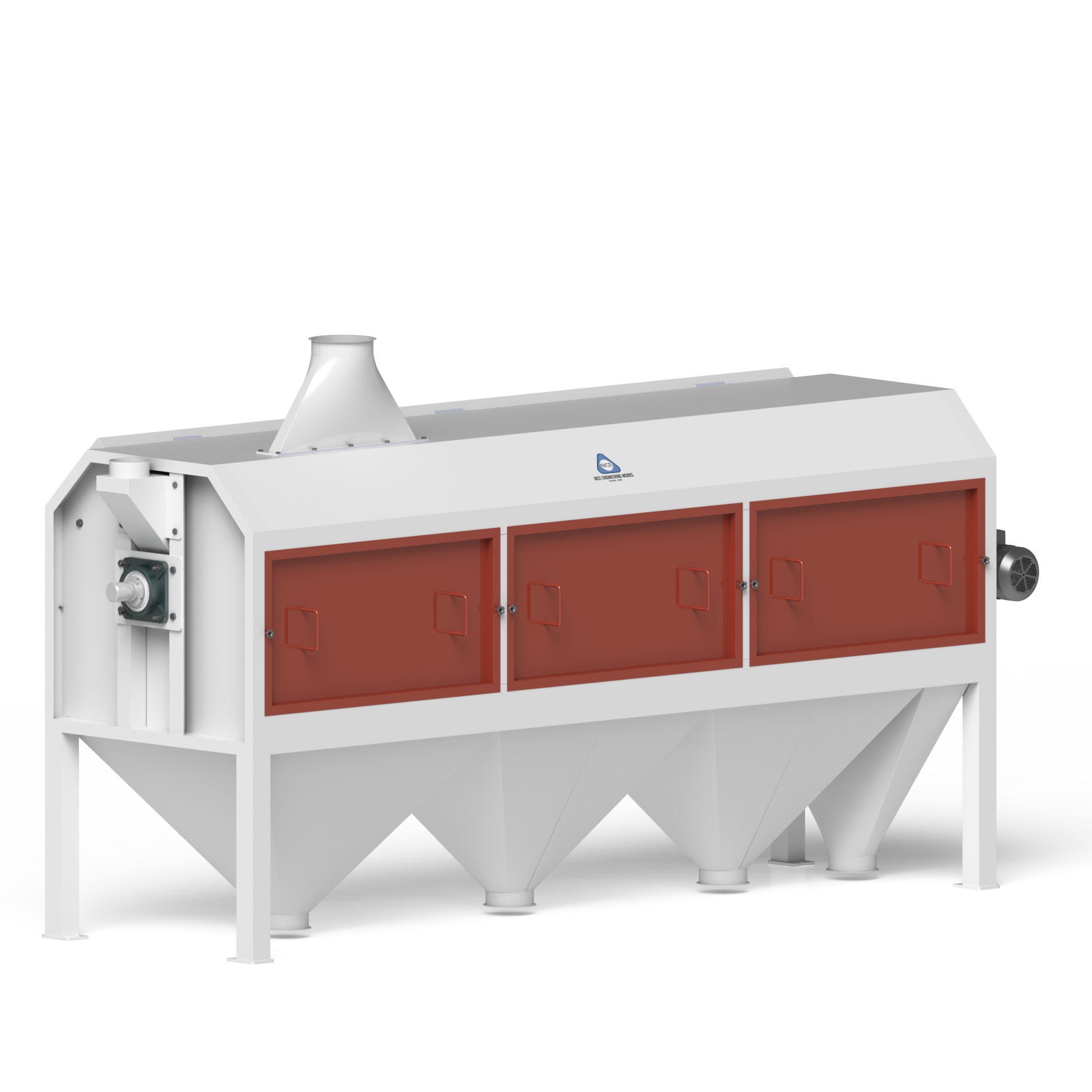

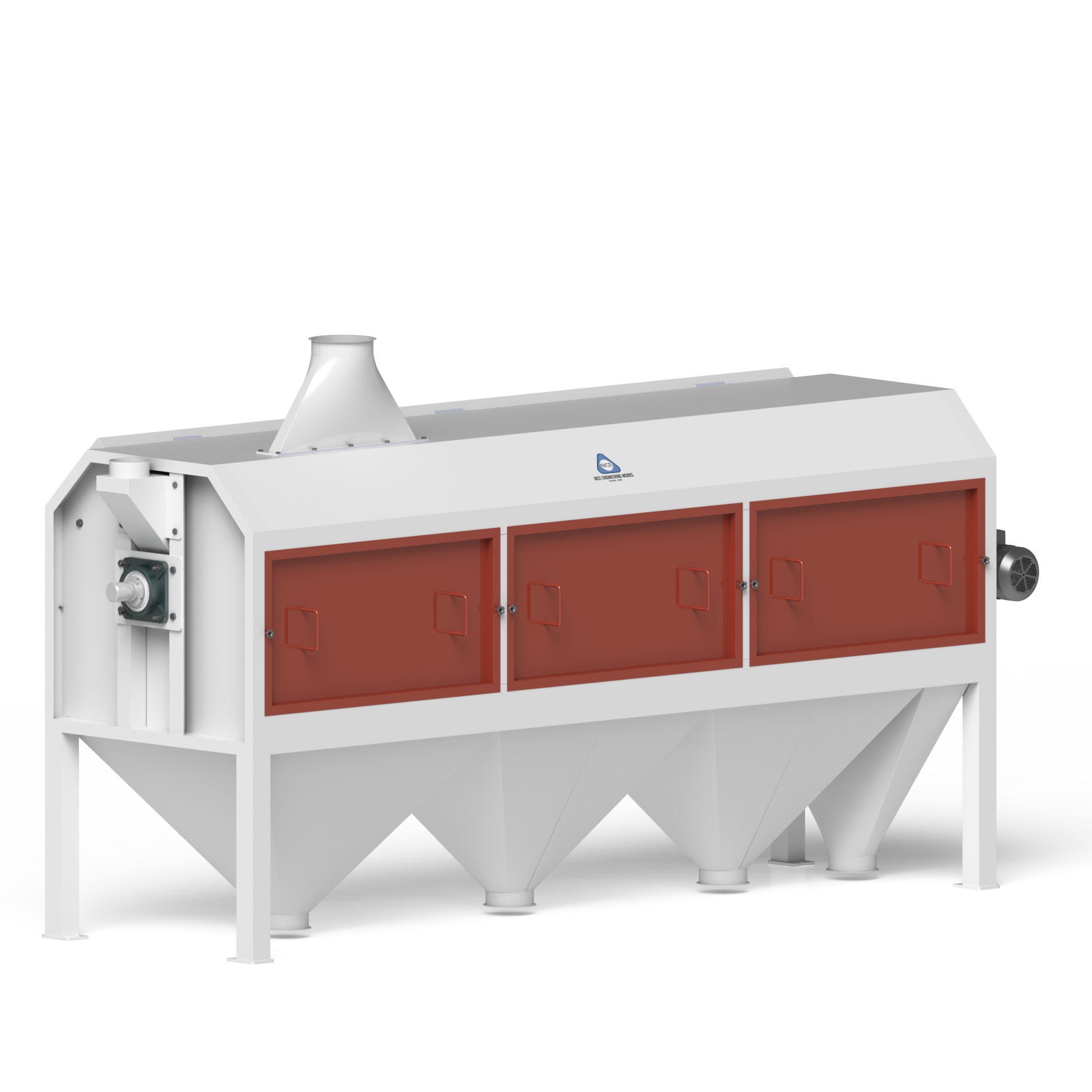

Utilization

Nice Engineering Works is introducing the Dryer. A dryer is a machine that is used to dry pulses such tur dal, urad dal, chana dal, masoor dal, and moong dal. It’s a common piece of machinery in Dal Mills and Food Processing Facilities.

Operation

Dryers remove moisture from grains by pumping heated air over them. The hot air can be produced using a variety of methods, including electricity, natural gas, or coal. Dryers come in a variety of sizes and capacities, and they can be customised to match the user’s exact requirements.

Features

- Minimum Maintenance.

- Low Energy Consumption.

- Flexible Modular Constructing.

- Large volume capacity available.

- Extremely user – friendly controls.

- Highest quality materials ensuring long life.

- Remarkably gentle processing of the grain.

- Suitable for indoor and outdoor installation.

- Easy access throughout for inspection purposes.

- High performance fans and air heating technology.

- Scientifically fitted finned tubes provides, no heat recovery.

- Uniform product moisture by modern discharge technology.

- Optimum energy savings by circulating air and heat recovery.

- Quick and steady moisture removing without hurting paddy quality.

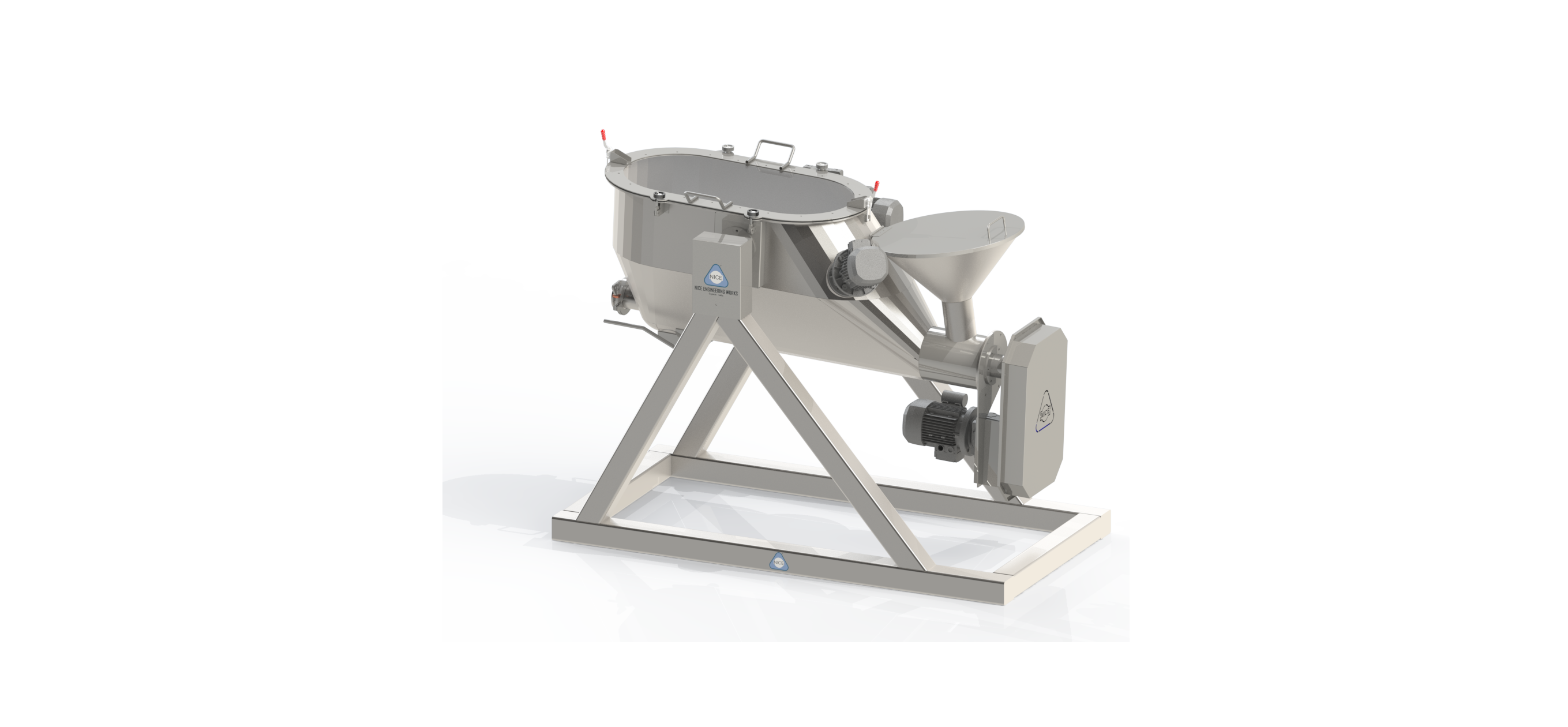

Utilization

Nice Engineering Works Introducing the Mixranum Machine, designed to exceed your expectations for profitability, efficiency, and effortless maintenance. This cutting-edge solution combines advanced material mixing capabilities with automation features and a robust design.

Operation

Easy assembly and cleaning are important features in our mixranum machine, especially in industries with frequent product changeovers. The process begins as the material is introduced into the machine through the side inlet hopper, where it encounters a precisely engineered shaft with a screw. This screw plays a pivotal role in mixing the material as it rotates. The Mixranum machine boasts three motors, each with a distinct function: one motor powers the rotation of the screw and blends the material. The second motor is used to break the lump and blend the materials properly, and the third motor rotates the position of the machine. For precise control over material discharge, a knob is thoughtfully installed to facilitate the opening and closing of the outlet, allowing the material to exit the machine as needed.

Feature

Easily removable Screw

Easy Screening

Adaptable Orientation

Low maintenance

Fully Automatic and Semi-Automatic options

User-Friendly Operation

Space Efficiency

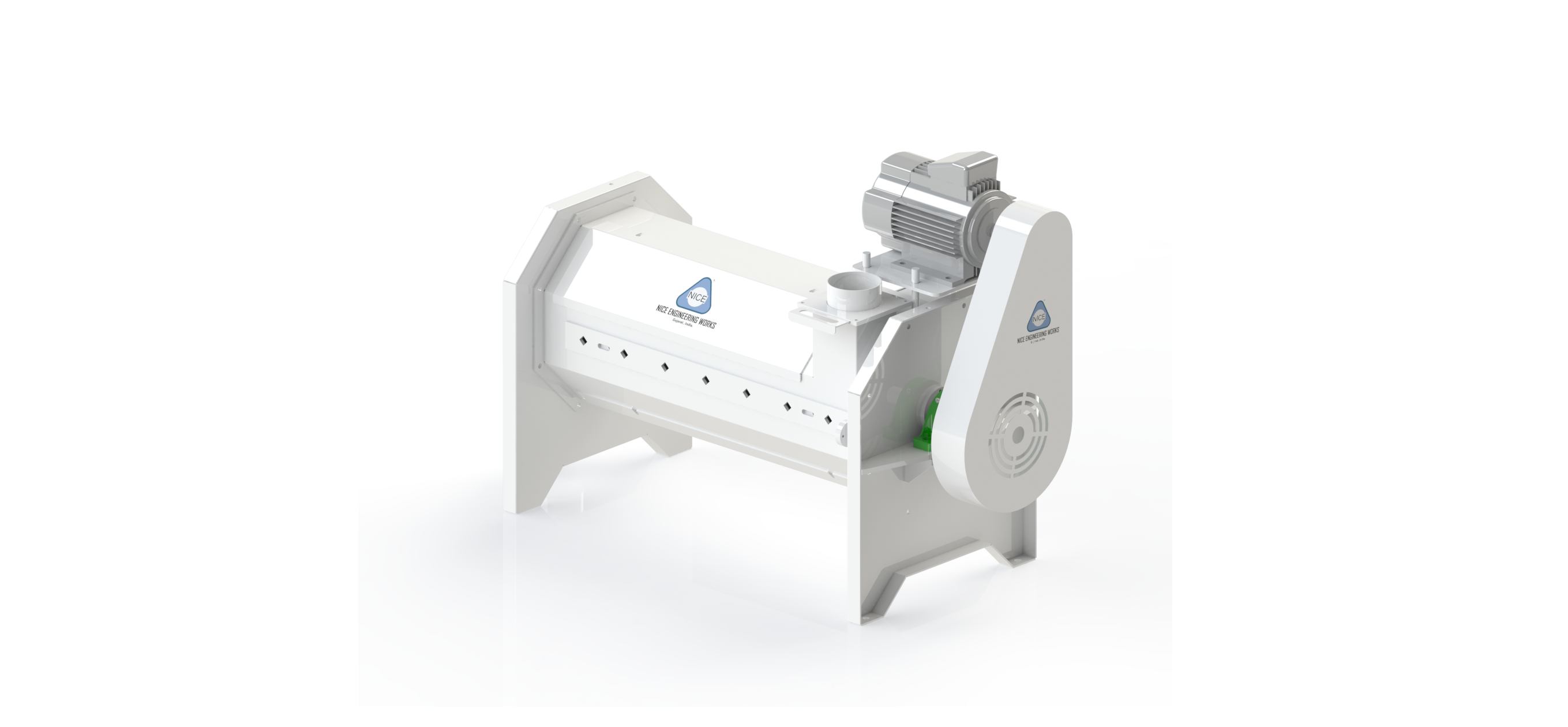

Utilization

At Nice Engineering Works, we take pride in our position as a leading producer of high-quality food processing equipment. Our commitment to delivering highly efficient and consistently productive machines that can operate round the clock has driven us to continuous innovation. The result of our untiring efforts and dedication is the Reel Machine, a specialized equipment designed specifically for processing wide range of applications.

Operation

An inlet cover that is mounted on top of the machine, which then separates the pure substance from impurities like sticks, husk, and leaves, can be removed. Seeds Cleaning and pulse processing plants use it to remove impurities from its products by screening process.

Feature

- Customizable Sieving

- Efficient Dust Separation

- Top-Mounted Inlet Hopper

- Bottom-Mounted Outlet Hopper

- Reliable Performance

Utlization

At Nice Engineering Works, we are committed to the success and profitability of our customers. To help you achieve your goals, we are proud to present our highly efficient Cumin Seed Cutter, specially designed for processing cumin seeds (Jeera). With cutting-edge technology and a focus on precision, our Cumin Seed Cutter is the ideal solution for streamlining your cumin seed processing operations.

Operation

The operation of our Cumin Seed Cutter is designed to be both straightforward and highly efficient. It begins with the introduction of cumin seeds through the conveniently located inlet at the top of the machine. To ensure precise control over the material flow, an inlet controller is provided, allowing you to adjust the rate of input as needed. Once the cumin seeds enter the machine, our Cumin Seed Cutter goes to work, meticulously removing any unwanted parts with precision and accuracy. This crucial step ensures that only the finest quality cumin seeds proceed through the process. After the removal of these undesired elements, the processed cumin seeds exit through the outlet, ready for the next phase of your production process. To maintain the purity of the final product, any separated unwanted parts are efficiently and conveniently removed through a designated cleaning door.

Feature

- Low Maintenance

- Fully Automatic

- Easy to operate

- Space-Efficient Design

The Nice Engineering Works Metal Detector is a high-performance tool that may be used for a wide range of tasks. It is simple to use and detects all metal things accurately. Metal Detector is a dependable and accurate, suitable for a wide range of applications. It is simple to use and has a wide range of features that make it perfect for users.

Features:

- Adjustable sensitivity settings to detect metal objects of all sizes and types

- Visual and audible alerts for easy detection

- Lightweight and ergonomic design for comfortable use

- Durable construction for long-lasting performance

- Easy to use

Utilization

Nice Engineering Works is introducing the Packing Machine. This packing machine is a high-performance and reliable machine that can help businesses to improve their packing efficiency and product quality.

Operation

This packing machine is designed to greatly improve the speed and accuracy of packing. It includes a packing scale body, Bafang sewing machine, and 2.2m handwheel type lifting conveyor. It has automatic weighing, filling, sewing, thread cutting, date printing, high accuracy and stable ability, a high-precision controller that is easy to operate, automatic error correction, auto alarm for over and under tolerance, fault auto diagnosis, one key recovery function, and super filter function of anti-vibration, anti-interference, to ensure weighing process stable and accurate.

Features:

- Automatic weighing, filling, sewing, thread cutting, and date printing

- High accuracy and stable ability

- High-precision controller that is easy to operate

- Automatic error correction

- Auto alarm for over and under tolerance

- Fault auto diagnosis

- One key recovery function

- Super filter function of anti-vibration, anti-interference

Utilization

Nice Engineering Works is introducing a Colour Sorter Machine. A Colour Sorter Machine is an optical sorting equipment that detects and removes faults and foreign objects from a wide range of products. Colour Sorter Machines can be found in a variety of industries, including food processing and agriculture. Colour Sorter Machines are an extremely adaptable and effective tool for sorting a wide variety of items.

Operation

Colour Sorter Machines work by passing products in front of a series of high-resolution cameras. The cameras capture photos of the products from various angles and at various light wavelengths. When a fault or foreign material is found, the Colour Sorter Machine removes it from the product stream using a variety of methods. It will separate the material based on the Product Colours.

Features

- Improved product quality

- Reduced waste

- Increased productivity

- Improved food safety

- Colour Wise Selection of the Products

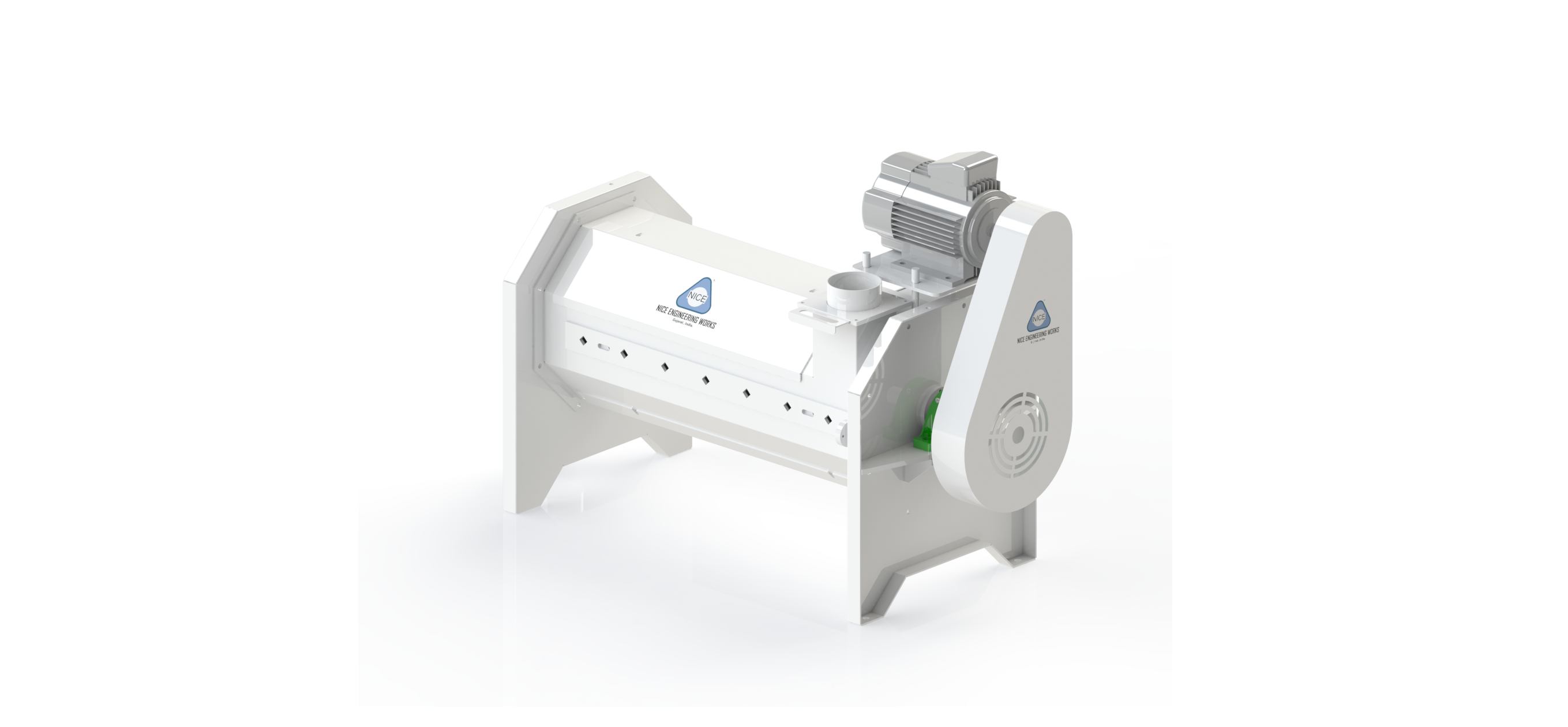

Operation

Entoleter is used to make sure the quality of the finished product. The Nice Engineering Work’s Entoleter machine is a high speed machine which disinfect the flour by destroying insects before packing of the materials. It also functions as a high-speed mixer, combining Micro-Nutrients and other preservatives with the flour prior to packaging. It extends the storage life of the products.

Features

- High Speed.

- Durable and long life.

- Extreme motor power.

- Simple to use.

- long life of spare parts.

Utilization

A huller machine is an agricultural machine that automates the process of removing the husks from grains.

Operations

A variable flow entrance allows the raw materials to enter the machine. Materials drop on the rotor, which is perfectly aligned and accelerated for a perfect horizontal impact. The impact ring is constantly moving up and down in order to distribute the impact zone. The husk separates from the kernel and is deflected downwards to the outlet pipe.

Features

- Excellent hulling performance

- Designed to last a long time

- Application flexibility

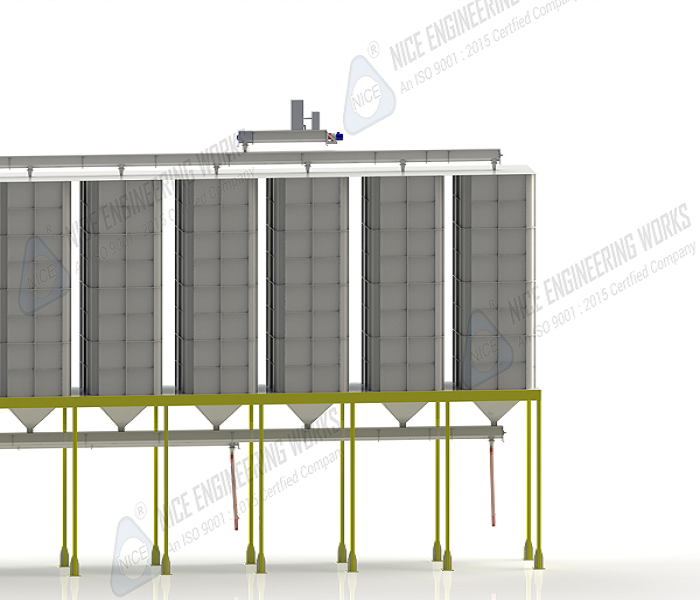

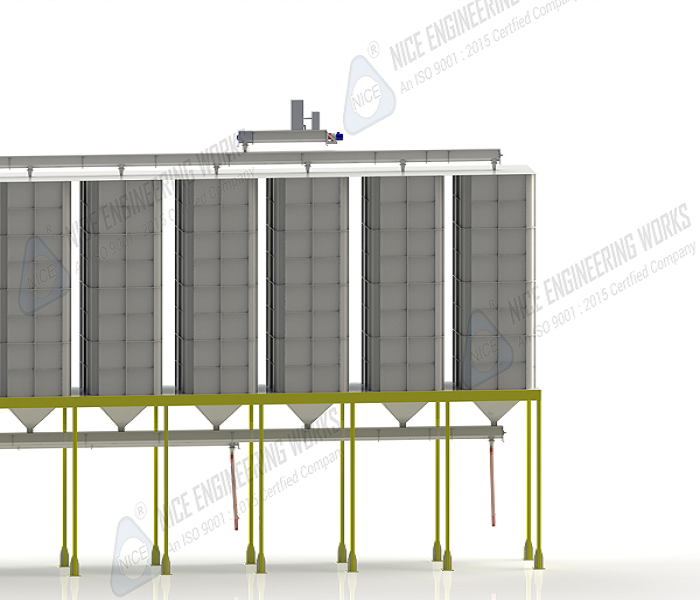

A silo is a structure for storing grain and bulk materials, where material pours in continuously. We have made various storage bins with customizable sizes. Bins are manufactured in the factory as well as on sight using S.S., M.S. material that has a handling capacity of 10-150 ton. However, bins are carefully engineered and designed. Fumigation is applied to the Bins to protect the raw material from pests and insects and to achieve hygiene. The Hull of the bins do not allow the grains to trap inside, hence our bins are super hygienic. We make special & tested bins to suit customer requirements.

Specification:

- Fumigated surface.

- Moisture proof.

- Fireproof.

- High-quality bins.

- Modular construction.

- customizable size.

+91 99786 77165/ +91 7069012352

+91 99786 77165/ +91 7069012352