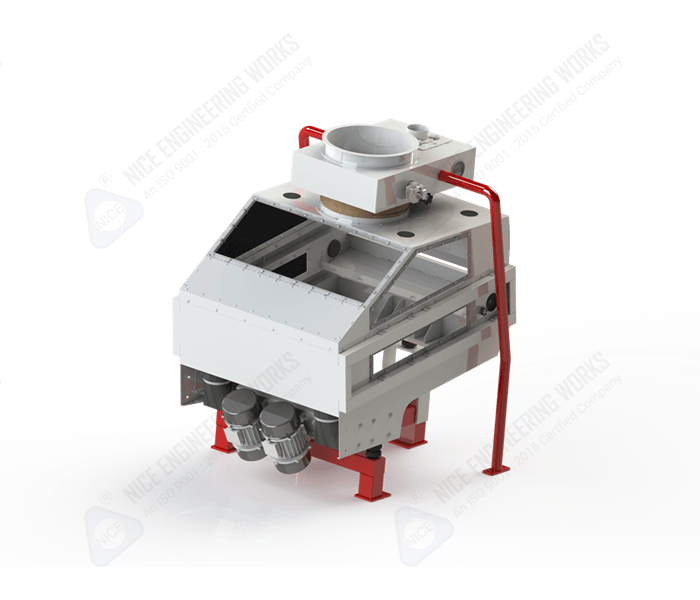

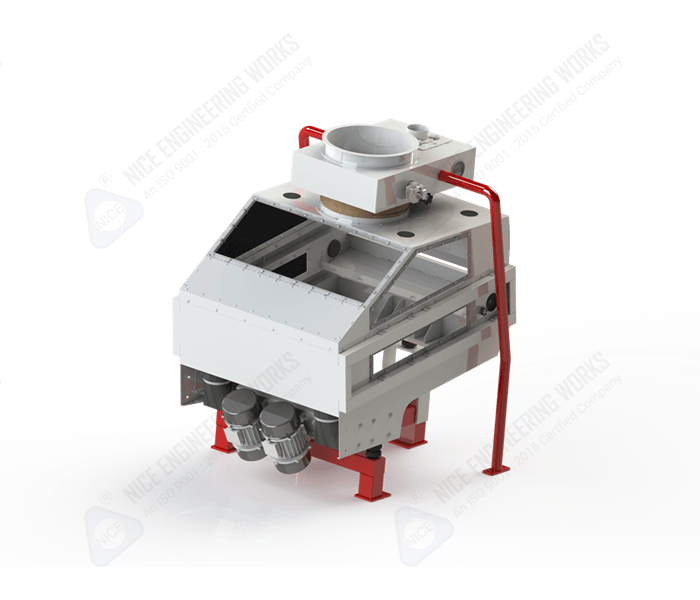

Utilization

To meet your expectations for profitability, efficiency, and effortlessness of maintenance. Introducing De-stoner, the latest in stone removing, automation, and have a robust design. De-stoner is employed in a variety of processes, including bulk material classification, cleaning and grading, and the elimination of high-density impurities.

Operation

The stock streams over the entire width of the machine with the help of a feeding device. The material first travels through the first screen. Since the air blows from bottom to top and a vibratory motor is attached, this screen avails the material to separate according to a specific weight. Lightweight particles flow on the upper deck pass with ease and get discharged from the outlet segment. And the heavy particles comprise glass, metal, and stones flow through the bottom.

Features

- Vibration motor responsible for oscillation.

- Built-in design.

- Adjustable sieve.

- High capacity and effortless maintenance.

- Easy to operate.

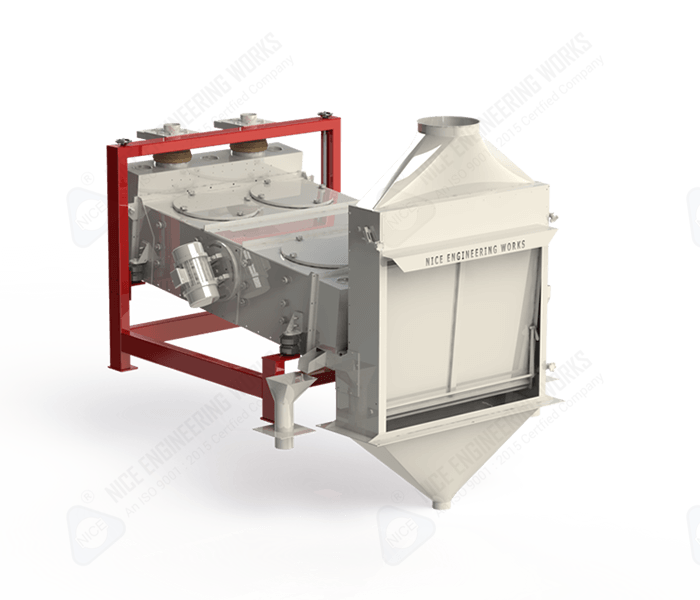

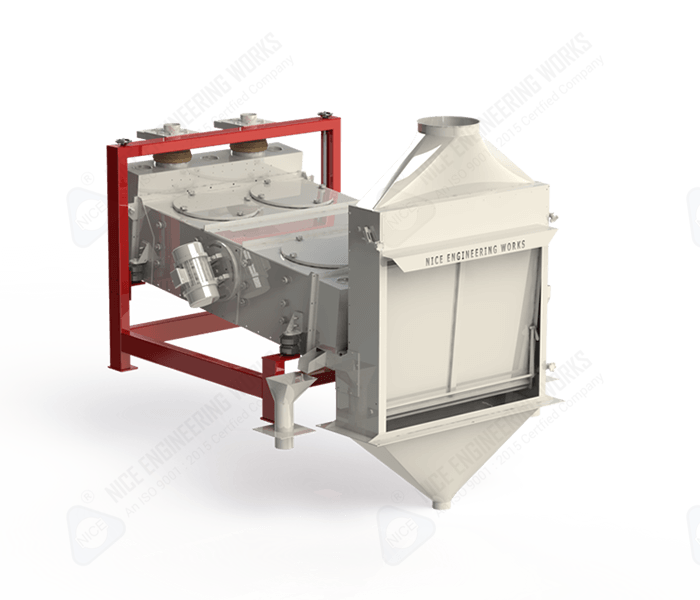

Utilization

The Classifier from Nice has a sturdy structure, optimizer screens, and an adjustable deck inclination. Various implementations make use of a classifier separator. Grains are cleaned with a classifier separator. Large impurities such as stick, husk, and leaves can be removed using this process. It uses screening to separate grain’s coarse and fine impurities and sorts a wide range of materials by size. Seed cleaning plants and pulse processing plants use it to remove fine dirt and sand from the products.

Operation

Vibrating screens are used, with the top screen removing large materials and the bottom screen removing fine dirt and sand. 2-Round covers are provided at the very top of the body for cleaning and inspecting. The machine’s vibration deck contains two vibratory motors, one on each side. The vibrating deck is supported by four hollow rubber foundations that reduce machine frame vibration. To make sieve changes easier, an inlet box wit a swing-down design is available.

Features

- Swing down pattern of Inlet box.

- As the inlet box is connected to the classifier’s body with movable hinge, with the help of this pattern the sieves of the classifier can be cleaned out easily.

- The essential classifier body consists of stainless and mild steel.

- Outlet box of the machine consist of multiple outlet segments.

- Customizable stroke.

- M.S. sieve frame for long life.

- Vibration motor responsible for oscillation.

- Adjustable throw angle.

- Inclination of the screen, designed to suit the workplace.

- Built-in design.

- High capacity and effortless maintenance.

Utilization

We care for the success and lucrativeness of our customers, to meet the calculations of our customers, We deliver a highly efficient Drum Sieve Machine with fast processing speed and a high degree of self-cleaning. Our Drum Sieve Machine perform a wide range of applications and work in all plant condition. Drum sieve Machine is used in Pre-Processing that includes Pre-cleaning, Removing high impurities, and De-husking.

Operation

An inlet cover is mounted on the top of the machine that avails the stock to get inside. The stock drops onto a rotating sieve. Sieve separates the pure substance from the coarse and stretchy material. Continuously moving particles sometimes block the sieve holes. To make the process smooth, a wire brush is fixed above the sieve that doesn’t let the machine get chocked. After the processing is done, impurities from the outer section are released.

Features

- Fast and easy screening.

- Low space and power requirement.

- High degree of self-cleaning.

- Built-in design.

- Fully automated.

- High capacity and effortless maintenance.

- Easily removable sieve.

+91 99786 77165/ +91 7069012352

+91 99786 77165/ +91 7069012352