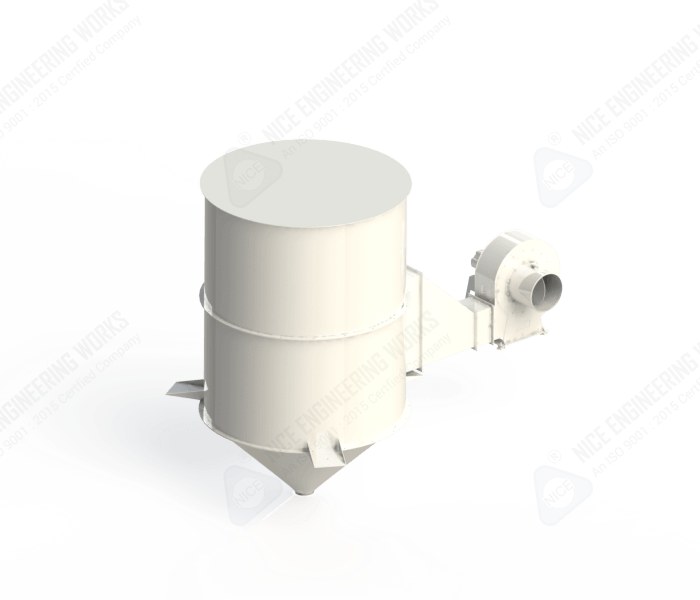

A Cooling silo is a structure for cooling grain and bulk materials, where material pours in continuously. Silos are fitted with a fan and air/moisture controller that reduces grain temperature and makes grains ready for further process. We have made various storage bins with customizable sizes. However, bins are carefully engineered and designed. Fumigation is applied to the Bins to protect the raw material from pests and insects and to achieve hygiene. The Hull of the bins do not allow the grains to trap inside, hence our bins are super hygienic. We make special & tested bins to suit customer requirements.

Specification

- Fumigated surface

- Moisture-proof

- Fireproof

- High-quality bins

- Modular construction

- customizable size

Utilization

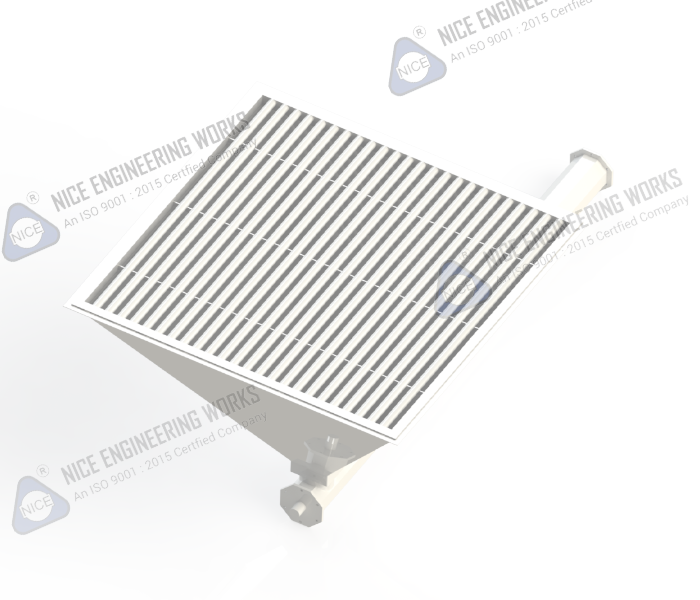

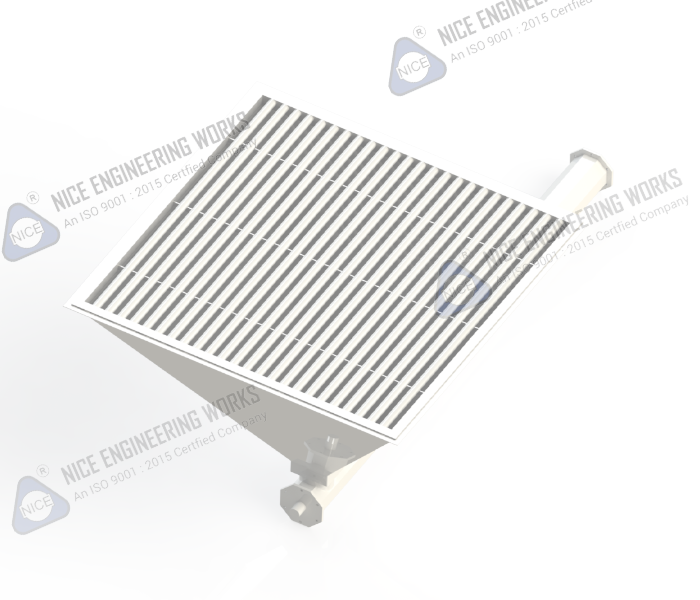

Intake Hoppers perform a tremendous amount of work. It has a structure with different shapes that stores bulk material. Our intake hoppers are efficient, capable, and sufficient for material intake. Intake Hoppers are used in almost every plant for handling raw material. Intake hoppers are suitable for the free-flowing product. We specialize in providing a wide range of high-quality intake Hoppers.

Features

- Heavy-duty body.

- Lifelong piece of equipment.

- Strong frame with little sway.

- Service is simple to obtain.

- Sharp throughput.

- Easy operation.

- Maintenance free.

Utilization

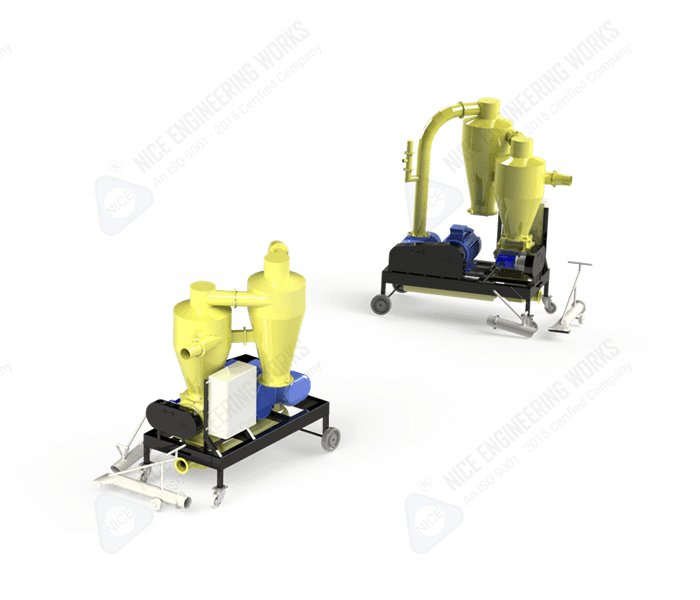

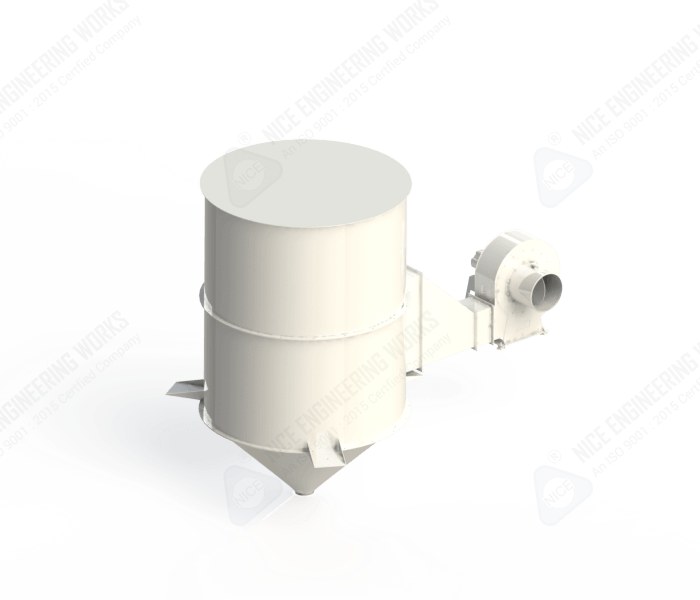

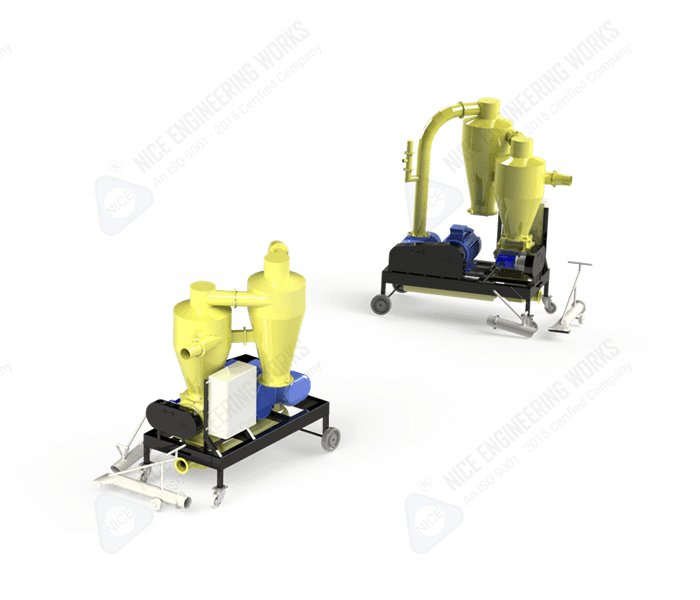

The Nice Bulk Material Conveying System is equipped with modern technologies. This machine is designed to minimize the plant load and labor work. A nice bulk material conveying system is an example of perfect engineering excellence. Working in grain dust is not easy and safe, breathing in grain dust can affect the lungs. The bulk material conveying system has been designed to consider workers’ health. NICE Engineering material conveying system is inaugurated to reduce human efforts and providing bulk grain handling capability to a single person.

Operation

Due to its engineered proficiency, our machine is designed for optimal performance. The material is drawn to the conical receptor that creates the cyclone effect. Thus, the Nice bulk Material conveying system act as a pre-cleaner. The receiver separates grain and grain dust. By the time dust reaches the labor lungs, Nice Bulk Material Conveying System collects dust, using cyclones. A metal box containing important electrical devices that control and monitor a mechanical process electrically. Maximum performance and lowest grain damage are achieved by the airlock. The airlock slowly rotates and feeds the product down the pressurized line. A Toolbox is inaugurated with this machine for the demonstration and experiment with the configuration setting. The tools are for quick access to common operations. The main system of the machine is a blower that rotates creating a lot of pressure to blow the product through the lines. The vacuum conveyor enables fast transit through workplaces and maintains motion regularly and smoothly. A pipeline or a vacuum-tight hose is utilized as the transport line. The vacuum conveyors use a pressure distinguishing system to move material from one end to another. Thus, vacuum conveyors are ideal for larger use where bulk material enters the conveyor.

Features

- Zero grain damage.

- Remove dust from grains.

- Easy handling.

- High suction power.

- Prevent grain dust from getting into the body.

- Cyclone ensures the optimum airflow.

- Easily movable from site to site.

- Flexible hose for flawless cleanout.

- Versatility in loading/unloading action.

Utilization

A pulverizer machine is used for seed, spice, and other agricultural products. A pulverizer is a mechanical instrument used to grind various types of material. Our pulverizer machine is manufactured with high accuracy and ensures sustainable operation. Spices like coriander, cumin, fennel, black pepper, cardamom, etc. are also continuously being processed in our machinery.

Operation

Pulverizer machine consists of protecting sieve, rolling blades, hard material flat bar, and the chassis. Material enters into the machine via an inlet hopper. The flat bars inside the machine are attached to the roller, grind the material finely. The material eventually drops onto the protecting sieve. This protecting sieve prevents the contaminated particles from entering into the material. Finally, the crushed material is collected by the way of the outlet box.

Features

- High accuracy.

- Sturdy design.

- Highly lucrative.

- Reliable performance.

- Long lasting.

- Low maintenance cost.

Utilization

Our professional designers and skilled Engineers have designed this machine in such a way that it lives up to all the expectations and forecasts of the customers. Our Emery Roll is used in a wide range of applications such as Pre-treatment, Obtaining gota, Dehusking grains, Rice, pulses, corn, and Separation of impurities.

Operation

This machine is simple in construction and easy to operate & maintain. The inlet box consists of a dead box with a magnetic inlet. Magnet in inlet box does not let any metal particle get inside. The Roller shaft is reinforced by a pedestal bearing. The horizontal Roller shaft rotates around the axis of the pedestal bearing. There is usually a 1.5-inch gap between the roll refill and inner sieve, to alter this gap an adjustable knob is mounted on the top of the machine. You can simply adjust processing speed with the help of an output slate valve. Finally, stock the drops onto the sieve following final processing. Eventually, the pure material is taken away from the outlet hopper.

Features

- Magnetic inlet.

- Adjustable sieve backed on the flange.

- Easy to operate.

- Adjust RPM with the help of frequency drive.

- Integrated design.

- Heavy-duty double roller bearing.

- Adjustable wheel mounted on the top.

Utilization

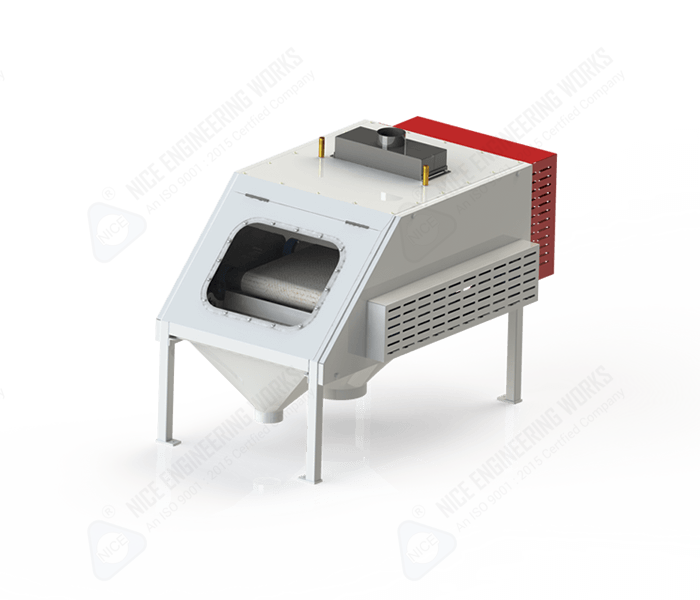

With a Powerful, Substantial, and Long-lasting structure, Dal Cooler performs numerous applications such as cooling, Drying, and absorbing. Dal Dryer is consists of a sturdy S.S./M.S. frame, two vibratory motors, a perforated Screen, High Power Air Blower And an outlet box.

Operation

Since it is an exposed structure, the material directly drops onto the perforated screen. Thereafter, the material spreads across the screen with the help of two powerful vibrating motors. A line of blower is placed beneath the perforated screen, used for generating the flow of air at substantial pressure. This flow of air eliminates the excessive amount of heat from the material and cools it down. Eventually, the unheated material is discharged from the outlet box.

Features

- Robust Design.

- Simple to clean and extremely hygienic.

- Minimum maintenance.

- High capacity and efficient.

- Durable and long life.

- Powder coated.

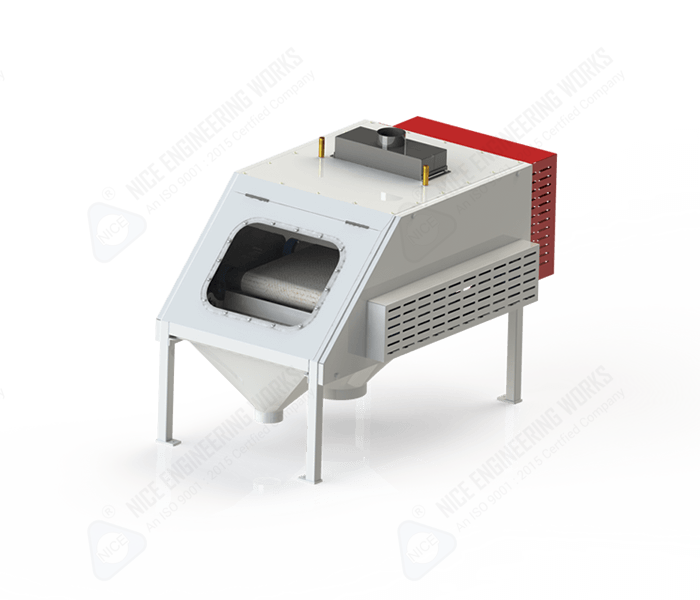

This machine dries the high moisture sesame seeds. The hot air produced by the centrifugal fan maintains the natural color and quality of the material. We use a high-quality glass wool blanket (50mm) for energy conservation. The exterior part of the machine is constructed by using stainless steel (SS-304). It has been designed with the latest technology. We inaugurated a new bearing system in a heavy-duty pendulum instead of an antiquated spring system. Spring damages more often, therefore, it demands high maintenance costs. Eventually, the spring system has now been replaced by a pendulum system. The pendulum deck works as a spreader that doesn’t allow the material to accumulate. Since it has a sieve door system, it cleans the material more efficiently. It has a very low maintenance cost.

Utilization

Twin Atta Chakki has Sturdy structure, High capacity, smooth operation, integrated design and fully automated. Atta Chakki used in various implementations. Cellar used in Flour Mill, Pulse Splitting.

Operation

The Raw material gets into the machine by the way of an inlet hopper. Two rolling stones crush the whole grain into fine flour. A hand operating knob placed under the inlet hopper flicks the slide gate, resulting in reducing the speed of the process. Vertical shaft and thrust bearing make the process smooth. Fine ground flour is subsequently thrown out with the help of the outlet segment.

Features

- Knob for Adjusting speed of material.

- High capacity.

- 5B pulleys for high grip.

- Vertical shaft and double bearing for smooth operation.

- Integrated design with S.S. body.

- Fully automated.

Utilization

We deliver highly efficient Magnetic separator Machine with fast processing speed and a high degree of self-cleaning. Our Magnetic separator works in all plant conditions and performs a wide range of applications. Magnetic Separator is used to remove heavy metal particles.

Operation

By the way of inlet hopper, the material falls onto the vibrating tray that is backed on spring. This vibrating tray scatter the material. The material then falls onto the endlessly moving belt, backed on two rollers. One of the two rollers is a magnetic roller that captures the metal particles. As the belt moves continuously, the particle goes downwards and falls where the magnetic field is exhausted. The final material is separated from the machine via outlet hopper.

Features

- Low operational cost.

- An improved feed system gives higher separation efficiency.

- Silent and smooth operation.

- This removes impurities that are larger, finer, and lighter than the main product itself.

Utilization

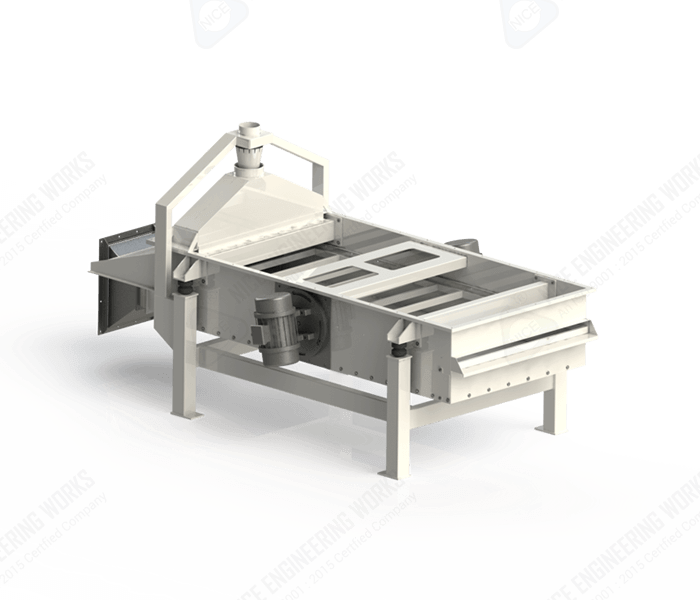

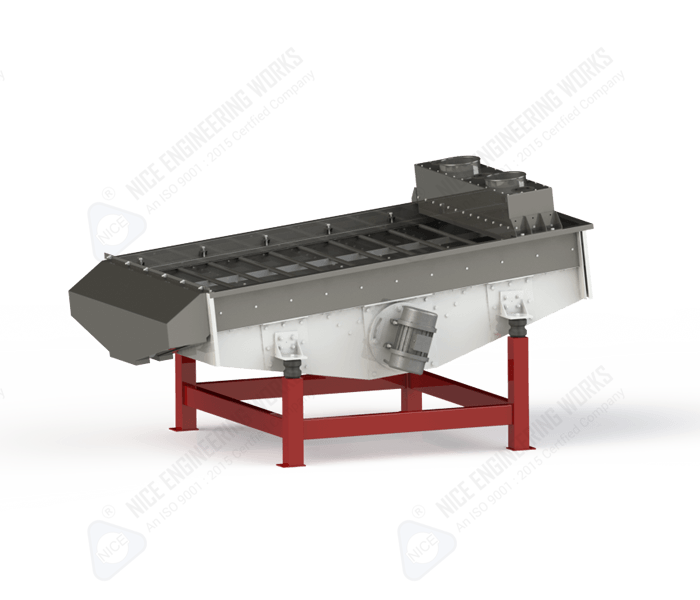

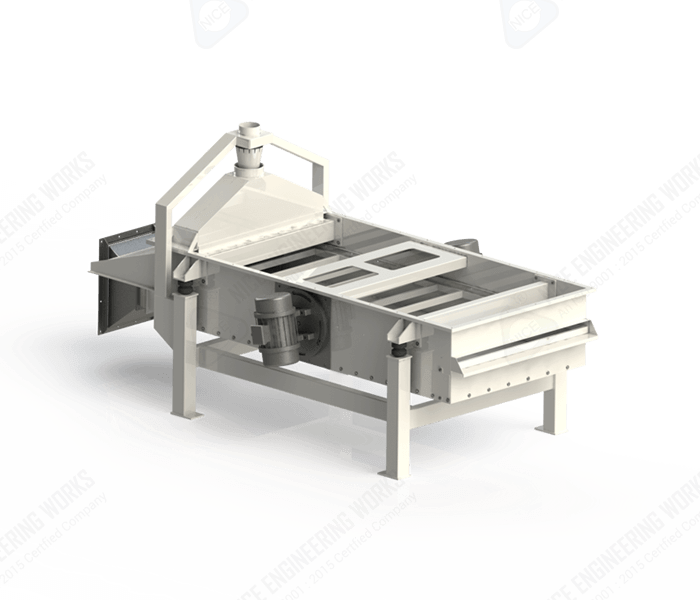

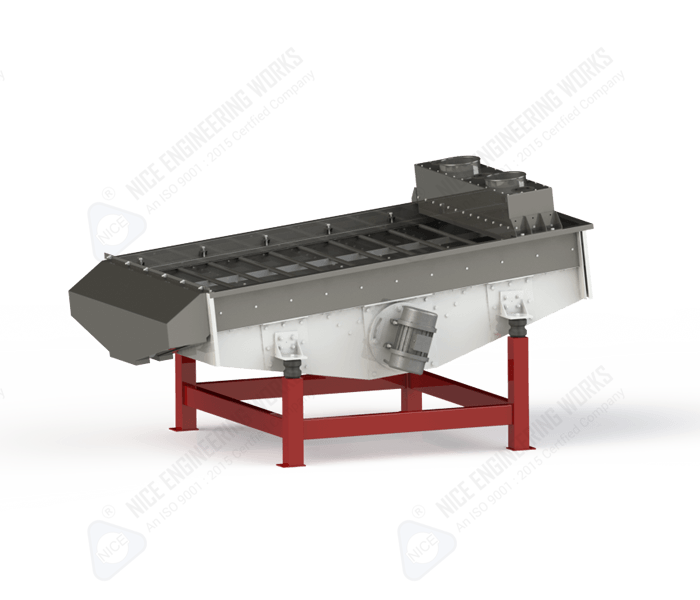

Vibro-separator is used in the various implementation. Vibro-separator is used in a wide range of applications such as removing large impurities like a stick, husk, and leaves. It separates coarse and fine impurities from grain via screening and classifies a broad range of materials according to size. It is also used for removing fine dirt and sand from products in seed cleaning plants and pulse processing plants.

Operation

The Vibro-separator is used to separate large and small unwanted substances from the grain. The machine comprises a vibrating chassis. The vibro separator is powered by two symmetric vibratory motors. The vibration level of the machine is adjusted by changing the inclination and adapting the counterweights of the motor. To suppress the vibration, rubber vibration dampers are used. The raw material is uniformly distributed on the sieves through the grain intake adjustment door. The Vibro separator consists of two layers of sieves, the first layer separates the bigger particles and the second layer separates the smaller particles.

Specification

- Inclination of the screen, designed to suit the workplace.

- High capacity and effortless maintenance.

- The essential body consists of stainless steel and mild steel.

- Built-in design.

Utilization

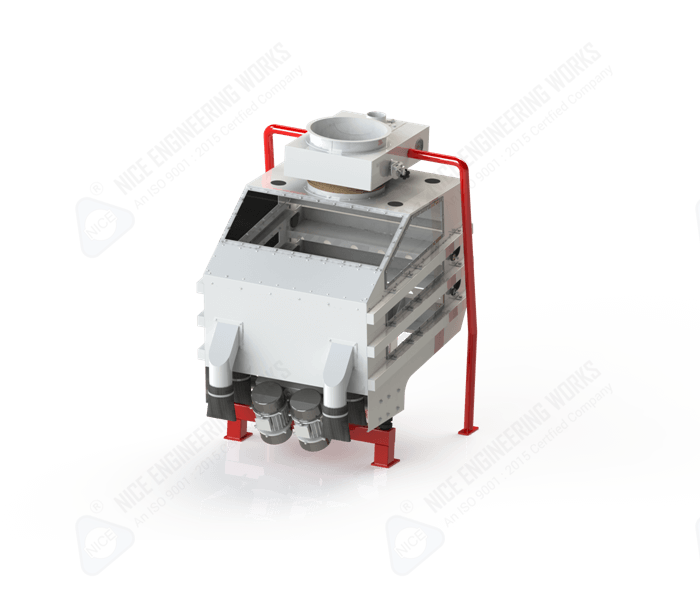

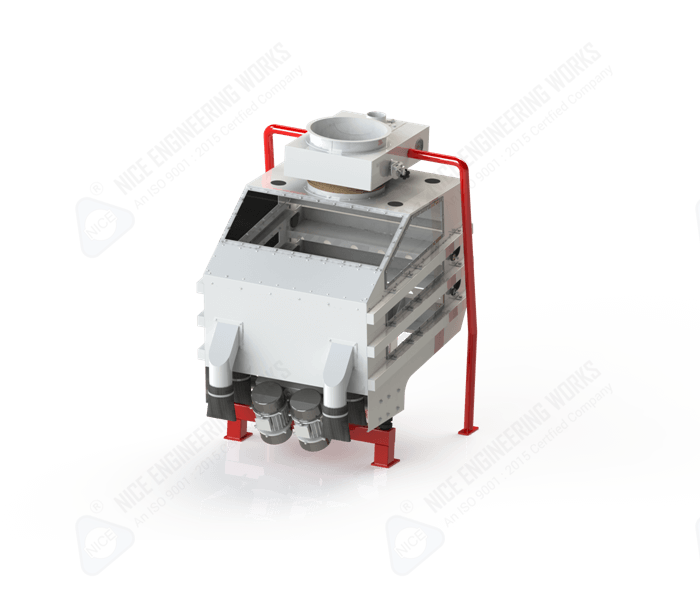

Gravity De-stoner is mainly used for removing stones. It also classifies heavy and light particles. It is mainly used for cleaning impurities in grain and granular materials.

Operation

Dense particles move slowly, Due to a difference in the suspended speed between grains and high-density particles(glass, stones, and metal). The vibration of the machine shifts these particles aside. consequently, the heavy impurities separate from the grain. Now, the material goes onto the second sieve where classification of the grain occurs. Eventually, low and high-quality grains from two different outlets are received.

Features

- Effective cleaning.

- Latest design.

- Low energy consumption.

- High capacity.

- Adjustable tilt angle.

Utilization

Nice Engineering works is a leading producer in producing food processing equipment. We deliver the highly efficient and productive machines that perform round the clock. Our untiring efforts and dedication towards transformation have helped us in innovating the Gravity Separator. Our Gravity Separator is used in a wide range of application, such as Categorization of bulk material, Cleaning and grading, Removal of high-density impurities. Gravity separator is used in separating impurities from wheat, barley, oats, rye, triticale, lentils, soybeans, peanuts, corn, sesame, Peas, beans, linseed, etc.

Operation

In order to separate particles based on their weight and density, gravity separators are frequently used. It’s one of the best ways to separate two things apart. It has a table for separating materials based on density. Gravity can be used to move any dry material across a table. The weight of the material is separated by the air pressure on the deck. A volume-adjustable air fan distributes air evenly across the vibrating deck, allowing you to regulate the deck’s air supply as needed.

Features

- Adjustable side tilt & eccentric speed.

- Customisable fan speed.

- Sharp throughput.

- Easy to operate.

- Integrated design.

- Highly efficient motors.

+91 99786 77165/ +91 7069012352

+91 99786 77165/ +91 7069012352