Utilization

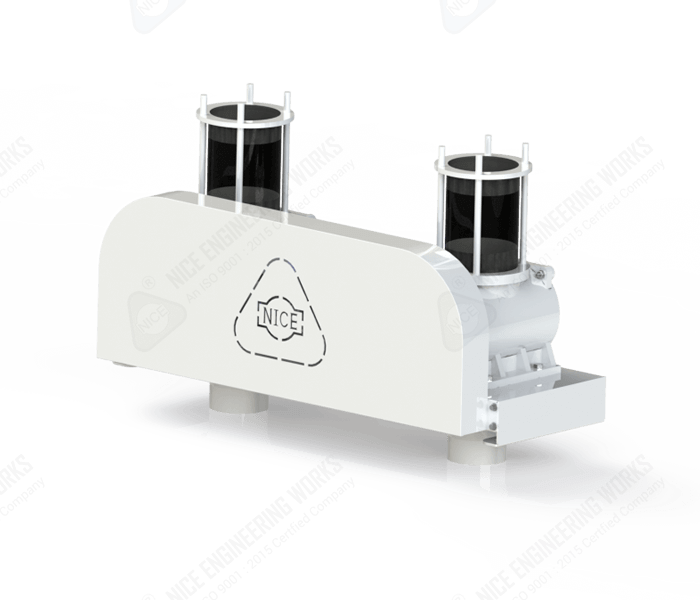

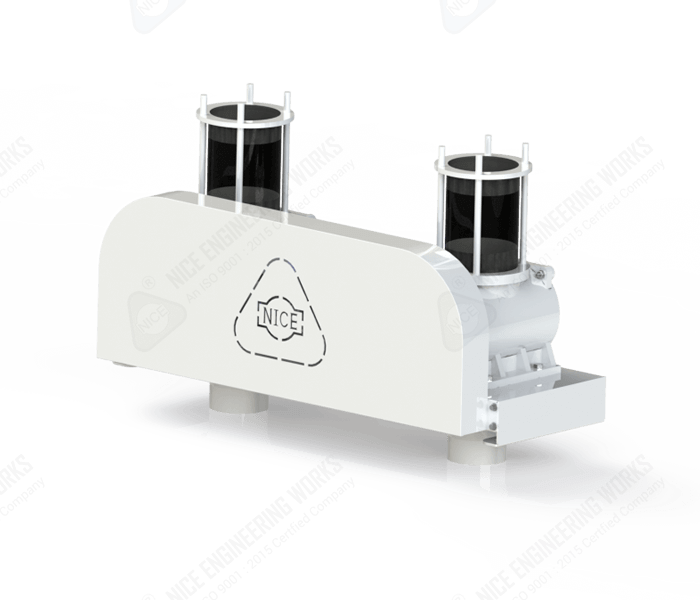

With Reliable performance, easy operation, and Excellent structure, we are introducing Airlock.The airlock is used in various implementations. It is mainly used for pneumatic conveying, dust control, and flow control.

Operation

The airlock device is composed of a rotary impeller that has both transmission and air-resistance functions. The airlock is used in many types of applications including conveying and controlling the material. Each application is slightly different and often requires a customized touch. We maintain an inventory of many different types of airlocks to quickly respond to virtually every situation. Factors such as pressure, heat, temperature, and the thousands of different product characteristics make the application of airlocks very difficult. Being willing to listen to the customer and having the insight and expertise to apply these is just as important to us.

Features

- Reliable performance and easy operation.

- Excellent structure and design.

- Hassle-free.

- Consist and tight clearance.

- Low space and low power required.

Utilization

With Reliable performance, easy operation, and Excellent structure we are introducing Airlock.

The airlock is used in various implementations. It is mainly used for pneumatic conveying, dust controlling, and flow control.

Operation

The airlock device is composed of a rotary impeller which has both transmission and air-resistance functions. The airlock is used in many types of applications including conveying and controlling the material. Each application is slightly different and often requires a customized touch. We maintain an inventory of many different types of airlocks to quickly respond to virtually every situation. Factors such as pressure, heat, temperature, and the thousands of different product characteristics make the application of airlocks very difficult. Being willing to listen to the customer and having the insight and expertise to apply these is just as important to us.

Features

- Reliable performance and easy operation.

- Excellent structure and design.

- Hassle-free.

- Consist and tight clearance.

- Low space and low power required.

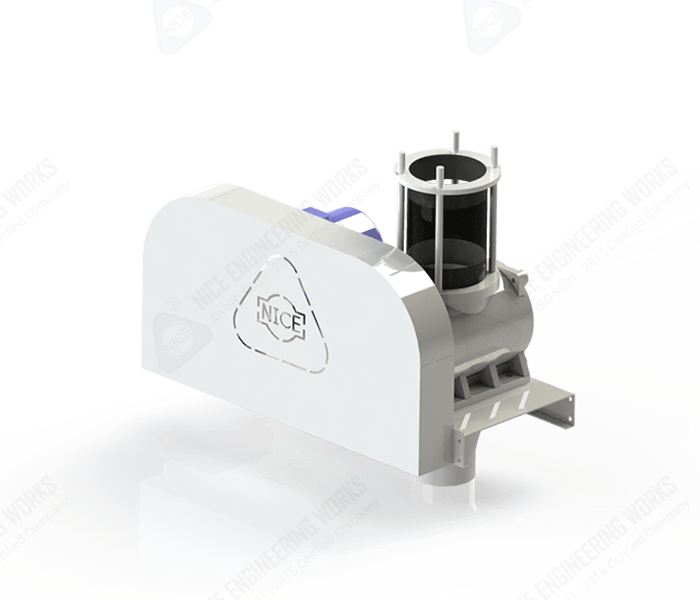

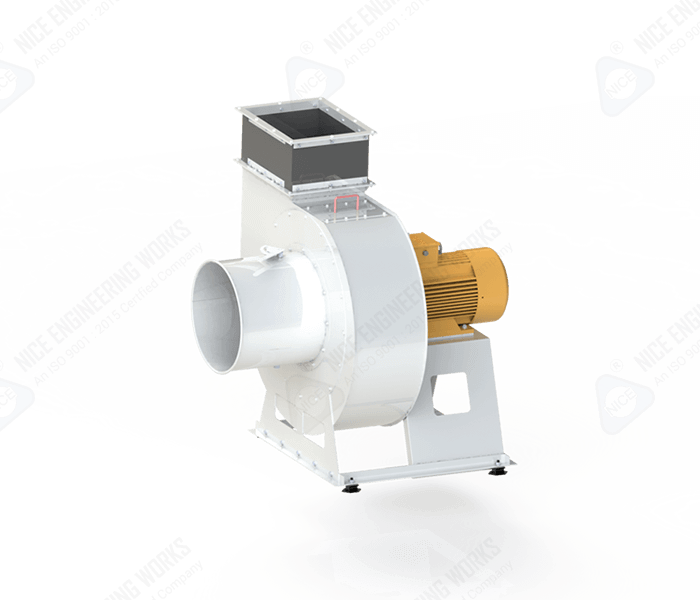

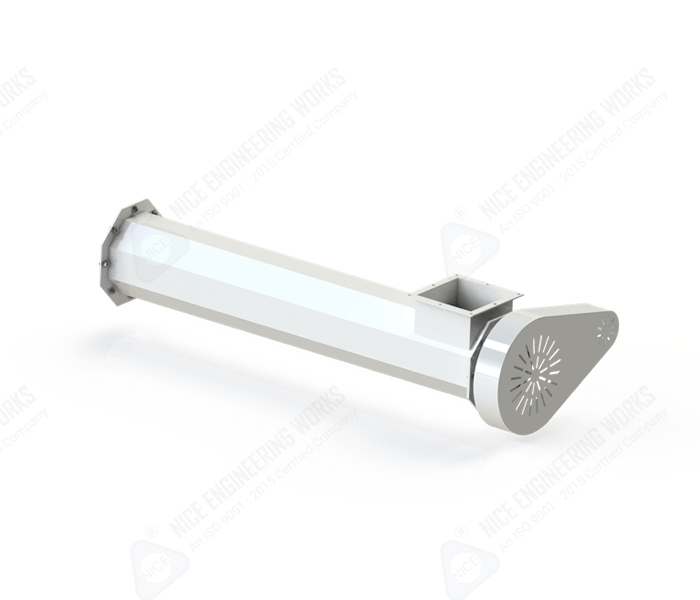

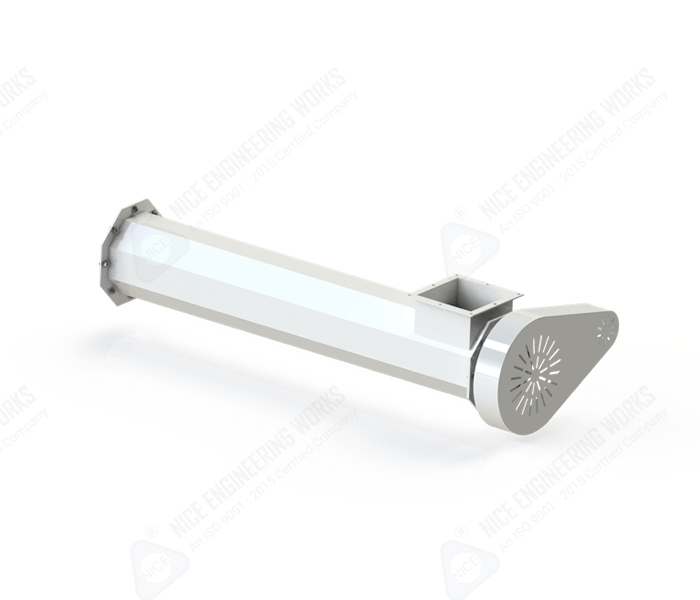

Utilization

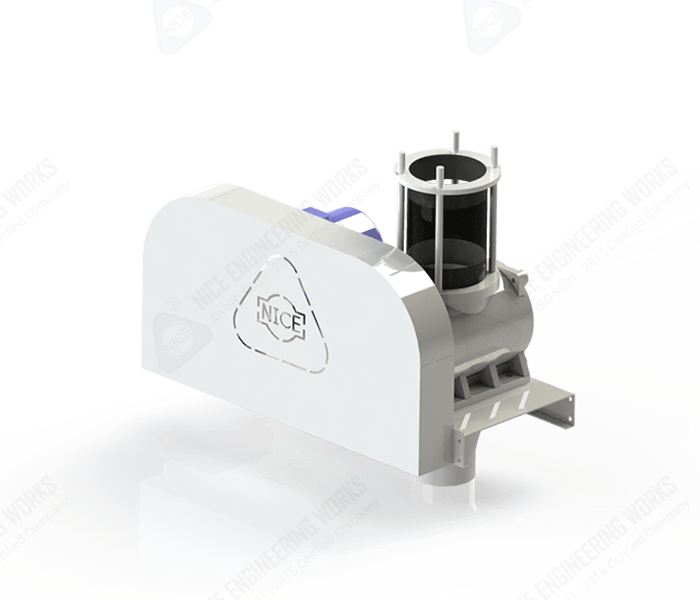

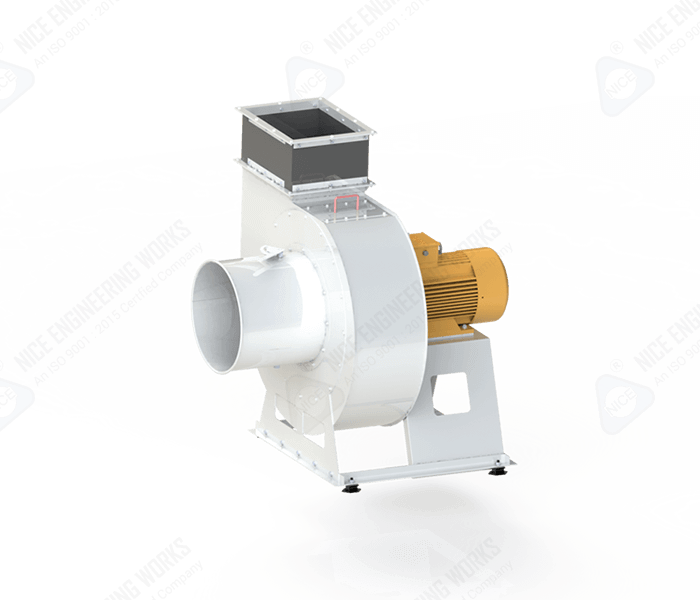

Nice deliver De-stoner fan with advanced design and high performance. The de-stoner fan is used in a wide range of applications such as Moving air, Discharging dust particles, and Discharging heat.

Operation

It radially shifts the air through a change in the airflow direction. One end of the housing (in which the radial fan is situated) is attached to the pipe. The pipe consists of a blocking valve that can be adjusted manually. The air or dust particle enters from the inlet segment, the fan turns the flow of air to the right angle. The shaft of the high-power motor is directly attached to the fan with a coupling. Impurities from the outer segment are released.

Features

- Valve for air adjustment.

- Multi oriented.

- High capacity and effortless maintenance.

- Sturdy design.

- Multipurpose.

- Manages humidity.

- Every part of the fan can easily be reassembled.

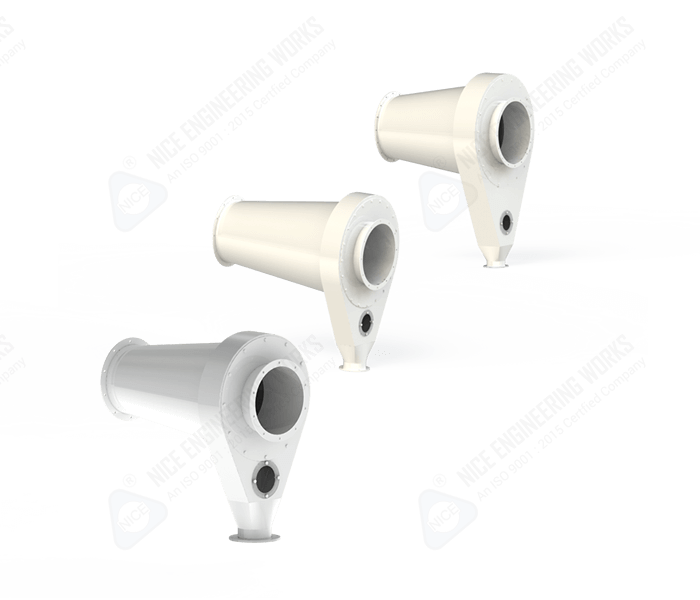

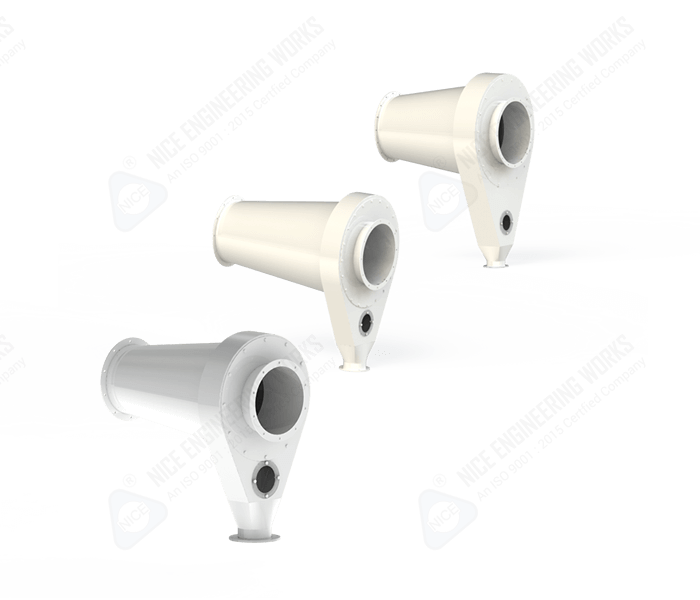

Utilization

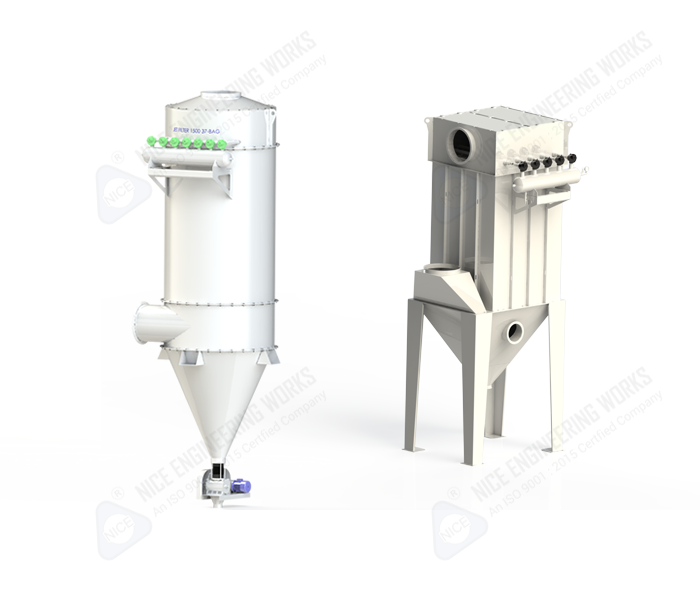

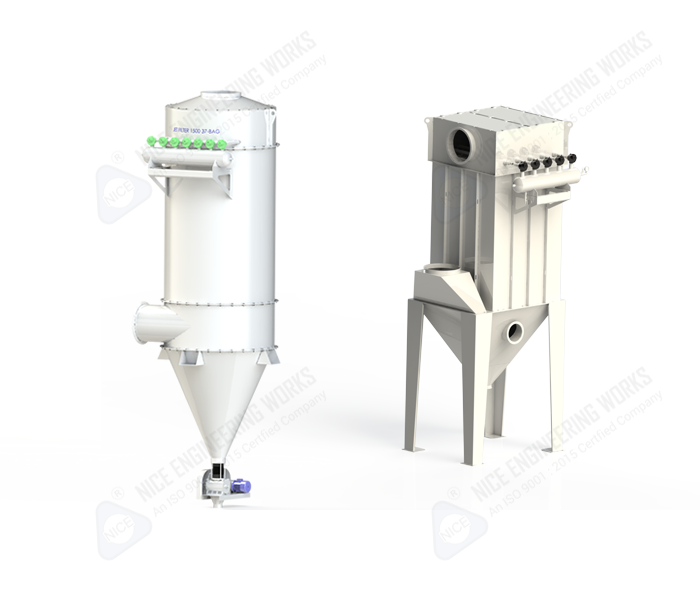

Cyclones are mechanical separators using centrifugal force to remove medium/large high-volume dust from the Grain, Pulses, and Rice. Many factors directly affect the efficiency of a cyclone. Physical limitations on-site sometimes limit the height available. Our engineers performed extensive testing to determine cone lengths that maximize efficiency yet keep plant restrictions in mind.

Operation

We pioneered the concept of keeping the inlet center line tangent to the outside edge of the cyclone. The smoother the inside surface, the more efficient the cyclone is. A fan blower is fixed on the top of the cyclone, it sucks duct particles by creating a suction and heavy particles drop downwards. Air volume, density, temperature, humidity, and product characteristics sometimes create complicated sets of criteria. Still, our process engineers have the experience and know-how to properly size and apply cyclones.

Features

- In-built design.

- Fast and easy operation.

- Fully automated.

- High capacity and effortless maintenance.

- separate effectively.

- lesser floor space is required.

Utilization

Cyclones are mechanical separators using centrifugal force to remove medium/large high-volume dust from the Grain, Pulses, and Rice.

Operation

Many factors directly affect the efficiency of a cyclone. Physical limitations on-site sometimes limit the height available. Our engineers performed extensive testing to determine cone lengths that maximize efficiency yet keep plant restrictions in mind. We pioneered the concept of keeping the inlet centreline tangent to the outside edge of the cyclone. The smoother the inside surface, the more efficient the cyclone is. A fan blower is fixed on the top of the cyclone, it sucks duct particles by creating suction and heavy particles are dropdown.Air volume, density, temperature, humidity, and product characteristics sometimes create complicated sets of criteria. Still, our process engineers have the experience and know-how to properly size and apply cyclones.

Features

- Well-built design.

- Fast and easy operation.

- Fully automated.

- High capacity and effortless maintenance.

Utilization

We have built this machine to keep an eye on dust. The pulse-jet filter is used for improving and enhancing the quality of air, It purifies the dirty and contaminated air.

Operation

Dusty and contaminated air passes through the inlet box. Heavy particles that come with dirty air fall because of the baffle plate. Further, contaminated air is passed through the chamber of filters where filtration is carried out. Particles that are deposited on the surface of the bag, while permitting the clean air to pass through, compressed air with high pressure blow into the filter tube. This compressed air leads the material to flow in the reverse direction. Subsequently, the material falls directly into the bucket at the bottom.

Features

- Highly efficient filter bags.

- Air-compressor tank for reverse flow.

- Air-lock at the bottom.

- Integrated design.

- High capacity.

- Low maintenance.

- Highly efficient Solenoid valve.

- Output nozzle for filter.

- Variable filtration device. for high efficiency filter.

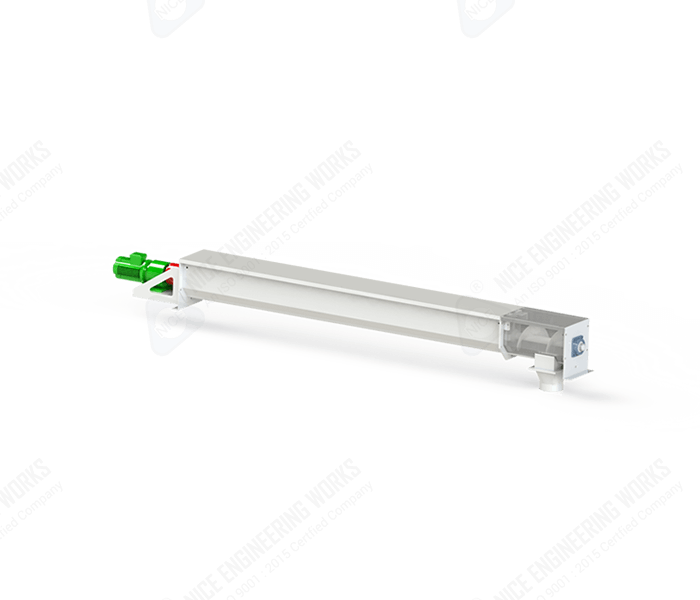

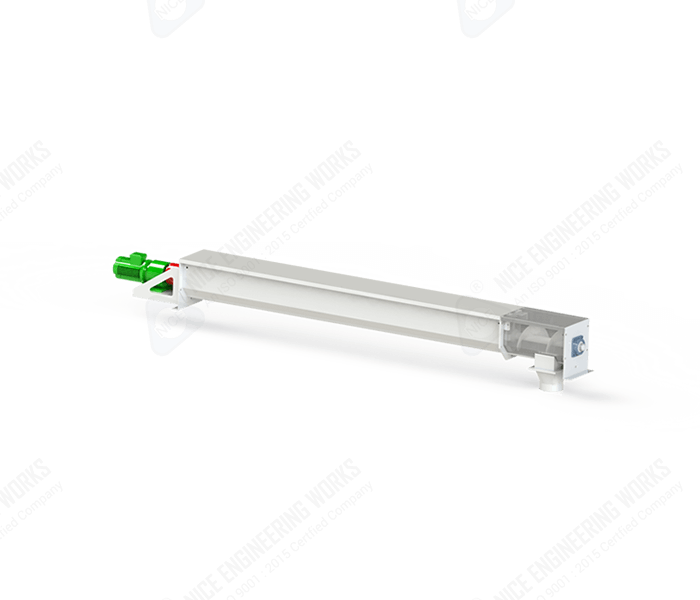

Utilization

We put adequate efforts working day and night to provide our customers satisfaction and complacency. A screw conveyor is used in conveying and handling. It is used in conveying material such as Cereal, Grain, and Pulses.

Operation

The material that is to be conveyed is fed by the inlet box. Endlessly rotating helical screw blades, attached with an elongated rotating tube assist the material to stir towards the destination. The helical blades are directly connected to the motor. Throughput speed depends upon the speed of the rotating motor. The size of the conveyor can be adjusted as per requirement.

Specification

- Powerful helical screw blade.

- Highly efficient gear motor.

- Frequency driver to alter the speed of feeder.

- 2.5mm S.S. body.

- Low maintenance cost.

- Inspection window for cleaning.

- Speed detector, overflow gate, or material level probe ensures optimal monitoring of performance.

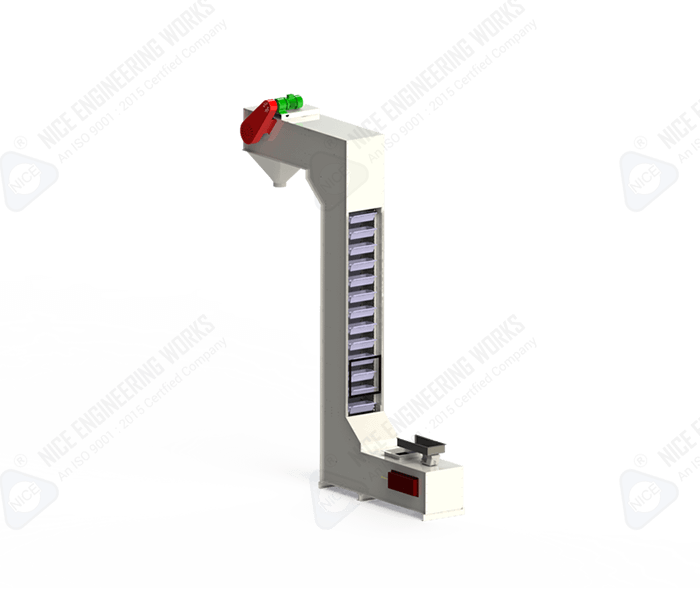

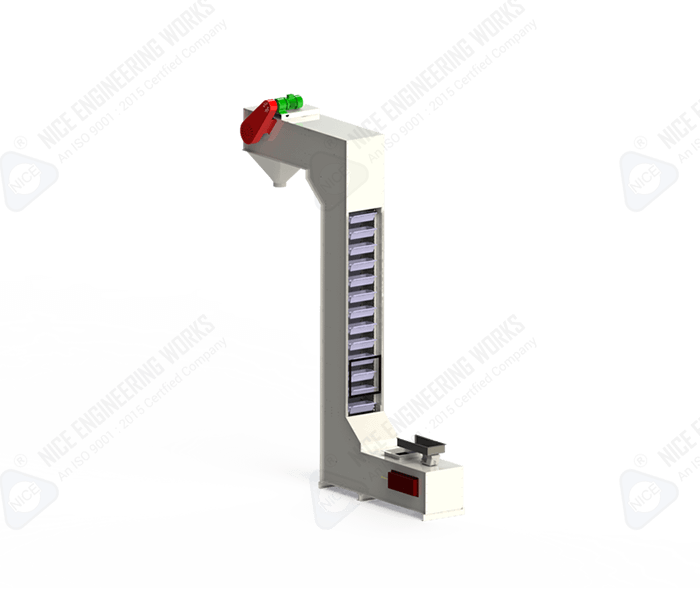

Utilization

With advanced design, High performing, and Fast processing, we are introducing a C-type Elevator. Since our machine has the highest throughput speed, it enhances the productivity of the plant and helps in minimizing human efforts. C-type bucket elevator is designed for a specific purpose to prevent the dust from flying around in the bucket elevator, and the length and height can be customized. C-type Bucket Elevator is used to transport pulses, grains, and other conveyable materials in major processing plants.

Operation

In a C-type bucket elevator, the raw materials are carried from the bottom to the top of the machine with the help of an endlessly rotating chain. It is usually enclosed, which prevents dust from flying around in the bucket elevator. It is either made of stainless steel or mild steel. It can fulfill multi-point discharge requirements at any position. Vibrating electromagnetic feeder in-take the material, from which the material falls onto the bucket. Both sides of the bucket are connected to the chain, which is backed by a chain sprocket. Motor mounted on the top with double chain sprocket. The chain moves continuously and endlessly, as a result, the goods reach their destination.

Specification

- Highly durable.

- Precise design.

- Easy chain installation and proper chain tensioning.

- customizable speed.

- Multi-discharge system.

Utilization

We put adequate efforts working day and night to provide our customers satisfaction. Our machine enhances the productivity of the plant and helps in minimizing human efforts. This machine is used in conveying and handling the material. It is used in conveying material such as Cereal, Grain, and Pulses, etc.

Operation

The material that is to be conveyed is fed by the inlet box. Endlessly rotating helical screw blades, attached with an elongated rotating tube assist the material to stir towards the destination. The helical blades that are attached to the shafting are directly connected to the motor. Throughput speed depends upon the speed of the rotating motor.

Specification

- 2.5 mm body with gear motor.

- Highly accurate.

- Low maintenance cost.

- 4 mm helical blade and pipe.

- Inspection window for cleaning.

- Speed detector, overflow gate, or material level probe ensures optimal monitoring of performance.

Utilization

High strength belt with heat resistant synthetic fiber, Integrated design, and fully automated, This is the Belt Conveyor from Nice. Belt conveyor is used in various implementations. The Belt conveyor is primarily used for conveying Grains, Pulses, and Rice, and smooth and rough material.

Operation

It is made up of many layers. At the top of the structure, a rubber belt is placed, made up of heat-resistant synthetic fiber that moves endlessly. Beneath the rubber belt, metal rollers are aligned to provide strength to the belt. These rollers play a helping hand for the belt to move. At both, ends of the conveyor two bearings are attached which makes the movement smooth. Gear motor is fixed on the head of the conveyor that drives the belt. A clear belt is adjusted just above the synthetic belt on both sides of the belt to prevent the material from getting stuck inside the machine.

Specification

- Bearings for smooth movement.

- Rollers to strengthen the belt.

- Durable and reliable.

- Fully automated.

- High strength fibre belt.

Utilization

With advanced design, Highly performing and Fast processing, we are introducing Z-Elevator from Nice. Since our machine has the highest throughput speed, it enhances the productivity of the plant and helps in minimizing human efforts. Z-elevator is used in the various implementation. It is mainly used in handling and conveying the material such as Rice, pulses, grains, spices lentils, Psyllium husk (Isabgol), cumin seeds, Cereals, Oats and Beans and many more.

Operation

Vibrating electromagnetic feeder in-take the material, from which the material falls onto the bucket. Both sides of the bucket are connected to the chain, which is backed by a chain sprocket. Motor mounted on the top with double chain sprocket. The chain moves continuously and endlessly, as a result, the goods reach their destination.

Specification

- Motor mounted on the top with double chain sprocket.

- Vibrating electromagnetic feeder.

- High quality bearings for smooth operation.

- Inspection glass for examining the process.

- Advance design.

- Fast processing

Utilization

With advanced design, Highly performing and Fast processing, we are introducing Bucket Elevator from Nice. Since our machine has the highest throughput speed, it enhances the productivity of the plant and helps in minimizing human efforts. Bucket elevator is used in the various implementation. It is mainly used in handling and conveying the material such as Rice, pulses, grains, spices lentils, Psyllium husk (Isabgol), cumin seeds, Cereals, Oats and Beans and many more.

Operation

It has three discharge sections, the middle/trunk section, and the bottom/intake section. The trunk sections can be added or removed to adjust the height of the elevator. It has an all-steel frame for rigidity with cross supports at regular intervals between the legs also doubling as built-in ladders. Buckets are attached at regular intervals and run over top and bottom crowned pulleys. It is provided with an enclosed Gear Motor. All bearings are of the Universal Flange Cartridge type which is known for their lifetime lubrication.

Specification

- High quality bearings for smooth operation.

- Advanced design.

- Fast processing.

- Self-lubricated bearings ensure less maintenance.

- Non-Magnetic fibre Bucket for long life.

+91 99786 77165/ +91 7069012352

+91 99786 77165/ +91 7069012352